Manufacturer of Sumitomo 130t All-Electric used Injection Molding Machine to Greenland Importers

Manufacturer of Sumitomo 130t All-Electric used Injection Molding Machine to Greenland Importers Detail:

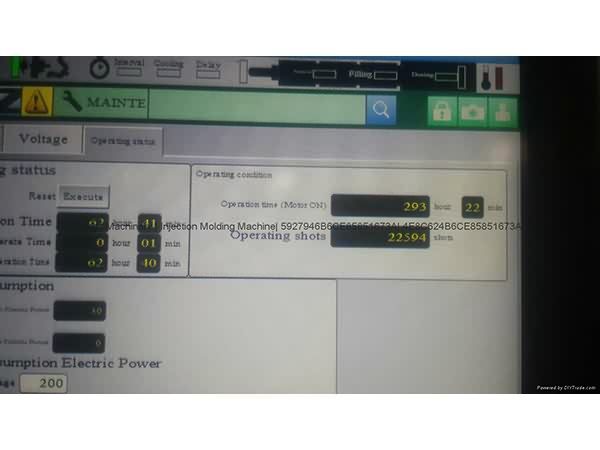

Sumitomo 130t All-Electric Used Injection Molding Machine Video: https://youtu.be/dh8sN_uCzjU Model: SE130EV-C360HP. Year: 2013. Screw diameter: 25/28mm. Injection Speed: 1000mm/s. Tie bar spacing: 510x510mm. 3 units. Machines are in very good and new running condition with less than 300 running hours. They are ultra high speed. Interested customers can visit our warehouse to inspect and test run machines.

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Precision of Plastic Machining

We will devote ourselves to providing our esteemed customers with the most enthusiastically thoughtful services for Manufacturer of Sumitomo 130t All-Electric used Injection Molding Machine to Greenland Importers, The product will supply to all over the world, such as: Nigeria , Orlando , Albania , In the future, we promise to keep offer the high quality and more cost-effective products, the more efficient after sales service to our all customers all over the world for the common development and the higher benefit.

Disney Collector brings you Play-Doh Peppa Pig stampers with Daddy pig, Mummy pig, Peppa pig and George pig stamps. In this video I'm also using the Talking Car Picnic Adventure.

Music from Kevin Macleod.

Disney Frozen Magic Color Changers Anna Coronation Dress.

Disney Frozen Anna Elsa Sleepover at Barbie Glam House.

Princess Sofia Royal Prep Academy Magical Talking Castle.

Play-Doh Meal Makin' Kitchen Princess Sofia the First.

Frozen Magiclip Glitter Glider Anna Elsa Olaf Magic Clip.

Glitter Glider Castle Set Disney Princess Magic Clip Dolls.

Glitter-Glider Dolls Magic clip Belle Rapunzel Elsa Anna.

Disney Frozen Dress-Up Magnetic Wooden Wardrobe Magnets.

Ariel Floating Fountain Color Changers Mermaid Sisters.

Disney Frozen Royal Closet Anna Elsa & Barbie Carry Case.

Play-doh Sofia the First Royal Tea Party w/ Doc McStuffins:

Disney Frozen Ice Skating Elsa & Ice Skating Princess Anna.

Princess Ariel Rapunzel Slumber Party Sleepover at Barbie.

New Sofia The First Royal Tea Party Picnic Doll 40 Phrases!

NEW Play-Doh Sofia the First Amulet Jewels Vanity Sparkle.

Sleeping Beauty Princess Aurora Color Changing Magic Dress.

https://www.youtube.com/user/DisneyCollectorBR/videos

Play-Doh Disney Princess Belle Royal Tea Party playdough.

https://www.youtube.com/user/DisneyCollectorBR/videos

Disney Princess Cinderella Royal Tea Party Time Belle.

https://www.youtube.com/user/DisneyCollectorBR/videos .

.

Check out reviews from Toycollector Blucollection at:

https://www.youtube.com/user/Blucollection .

Click to Subscribe DCTC Toys-Collector Unboxing Channel:

https://www.youtube.com/DCtoysCollector

Assista ao Canal Brasileiro de Brinquedos e Bonecas.

https://www.youtube.com/BrinquedoseBonecas

Call David Macdonald for more info on 03 9706 8066 or email sales@appliedmachinery.com.au.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.