Manufacturing Companies for JSWJ1300EIII used Injection Molding Machine to Slovak Republic Manufacturers

Manufacturing Companies for JSWJ1300EIII used Injection Molding Machine to Slovak Republic Manufacturers Detail:

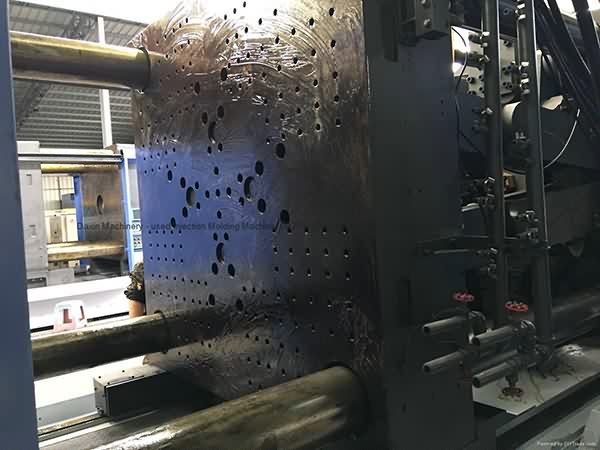

JSW 1600t used injection molding machine.

Model: J1300EIII.

Year: 2008.

Tie bar spacing: 1315x1270mm.

Screw diameter: 120mm.

Machine is in good working condition. Interested customer can visit our warehouse to inspect the machine and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

How Importers And Exporters Can Benefit From The Canton Fair

We also provide item sourcing and flight consolidation solutions. We have now our very own manufacturing facility and sourcing place of work. We could provide you with nearly every kind of merchandise associated to our merchandise variety for Manufacturing Companies for JSWJ1300EIII used Injection Molding Machine to Slovak Republic Manufacturers, The product will supply to all over the world, such as: Lithuania , United Arab emirates , Georgia , Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question items they do not understand. We break down people barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

Click below and get a wide information about this Used Machine: https://www.machinepoint.com/machinepoint/inventory.nsf/idmaquina/300034828?

Professional manufacturer of Recycling Equipment and Material Recovery Facility. Especially expertize in PET Recycling Machine, PET Recycling Equipment, PET Recycling Line, PET Recycling Plant, PET Recycling Machinery, PET Bottle Recycling Machine

This is the PET Recycling Line we installed in China.

1000kg/hr

A grade output

output chips/flakes are ready for synthetic fiber

IV: 0.7~0.8

Specification specified briefly as below:

PET Recycling Line -- A Grade output × 1000kg/hr

PET Recycling Line Length (measurement): 67M

PET Recycling Line Witdh (measurement) : 6.8M

PET Recycling Line Hight (measurement) : 4.5M

PET Recycling Line input capability: 1200~1500kg/hr

PET Recycling Line output capacity: 1000kg/hr (guarantee)

PET Recycling Line Power consumption: 282.5KW

PET Recycling Line Total Water consumption: 30M^3

PET Recycling Line Delivery time : 100Days

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!