Manufacturing Companies for Nanrong 120t used Injection Molding Machine to luzern Manufacturer

Manufacturing Companies for Nanrong 120t used Injection Molding Machine to luzern Manufacturer Detail:

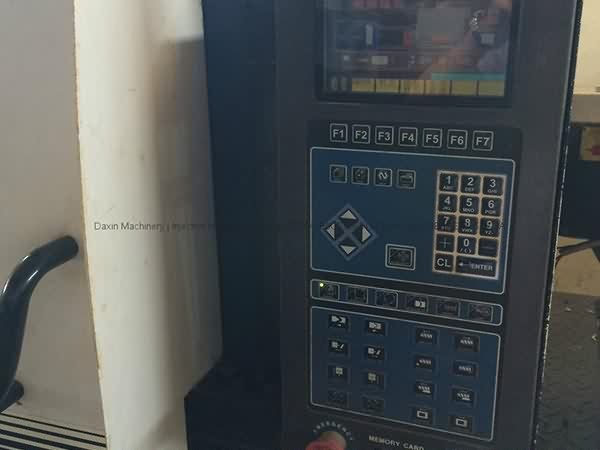

Taiwan Nanrong 120t Used Plastic Injection Molding Machine

Youtube Video: https://youtu.be/Dpld0N3LLpk

Model: 120SA

Tonnage: 120t

Screw diameter: 22mm

Tie bar spacing: 360x360mm

Year: 2006

Machines are in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou.Interested customers can visit us after Chinaplas to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Making Plastic – Plastic Injection Moulding

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for Manufacturing Companies for Nanrong 120t used Injection Molding Machine to luzern Manufacturer, The product will supply to all over the world, such as: Iran , USA , Moldova , As an experienced group we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of our company is to build up a satisfactory memory to all customers, and establish a long term win-win business relationship. Choose us, we always wait for your appearance!

Milacron VL600-76, 600ton, 95 ounce, CAMAC VEL controls, new 1994. for sale by owner 586.228.2100.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!