Massive Selection for JSWJ450EIII used Injection Molding Machine to Turin Factories

Massive Selection for JSWJ450EIII used Injection Molding Machine to Turin Factories Detail:

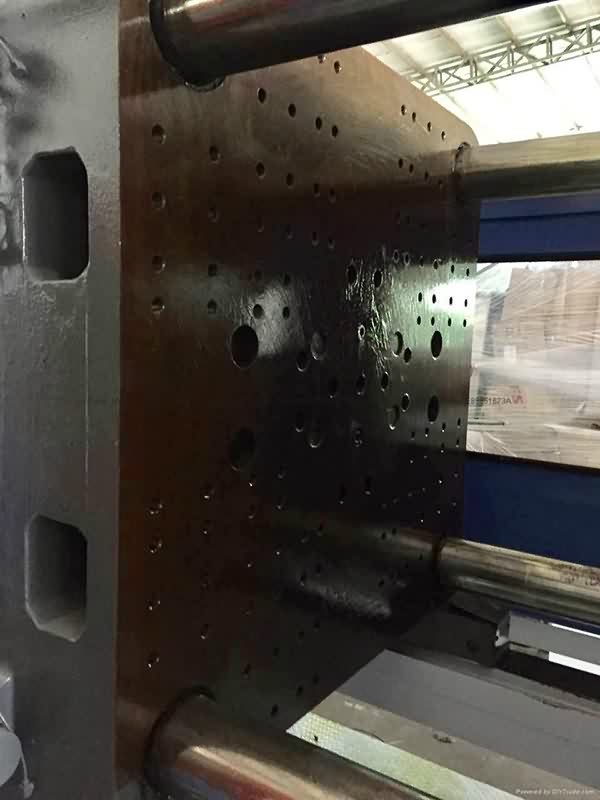

JSWJ450EIII used Injection Molding Machine.

Video:https://youtu.be/CXCqYjH1cto

Model: JSWJ450EIII.

Year: 2006.

Screw diameter: 84mm.

Tie bar spacing: 810x810mm.

Machine is in very good working condition. Interested customer is welcome to visit our warehouse to inspect the machine and test it running under power.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

Plastic Injection Molding: Past, Present and Future

The shopper satisfaction is our primary focus on. We uphold a consistent level of professionalism, quality, credibility and repair for Massive Selection for JSWJ450EIII used Injection Molding Machine to Turin Factories, The product will supply to all over the world, such as: Johor , Kuala Lumpur , Jeddah , Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of "human-oriented and faithful service", with an aim to gain global recognition and sustainable development.

Toshiba Machine’s Table-type Horizontal Boring and Milling Machine BTD-200QH is equipped with a 200mm diameter quill and designed with a remarkably robust and rigid spindle capable of powerful cutting .BTD-200QH is an easy-to-use machine, designed by providing a compact user friendly operator pendant not only for automatic operation but, also for manual functions.

5-axis operation is also available by supplementing a separate rotary table for the machining of complex work pieces.Moreover, with Automatic Pallet Changer and incorporating a newly developed electrical interphase for the rotary table ultimately leading to an extremely effective unmanned machine process with no operator intervention.Toshiba Machine shall continue to present new Technologies for the future and contribute to the development of our customer’s products to achieve efficient and profitable productivity.

Table-type Horizontal Boring and Milling Machine BTD-200QH

Toshiba Machine Official Hompage (Machine Tools)

https://www.toshiba-machine.co.jp/en/product/machinetool/lineup/b/btd200qh.html

Main features

1. Easy-to-operate compact pendant for manual machining operations

Most sophisticated CNC system TOSNUC 999

Wide table withstand heavy load and allows easy set-up

2. High rigidity bed supports the entire machine

3. B-axis drive mechanism provides high-speed and high-accuracy machining

4. 5000min-1 spindle with high-speed and high-torque specifications (option)

5. NC rotary milling operation (option)

Applicaiton of Manual mold silicone:

Manual mold silicone rubber is mainly used for model design of manual mold, PVC plastic mold, cement products, low melting point ally toy molds, alloy toy, plastic toys, electronics, handicrafts, stationery, large-scale sculpture, reproduction of culture relic, shoe sole molds, pad printing allocation, Electronic equipment antivibration and so on.

Contact: Ms Vicky (林苑如)

Tel: 0086-755-89948013

Fax: 0086-755-89948030

Mob: 0086-13751020433

E-mail: hyz@szrl.net

QQ: 379973354

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!