Massive Selection for Mitsubishi 1300t Used Injection Molding Machine to Romania Manufacturer

Massive Selection for Mitsubishi 1300t Used Injection Molding Machine to Romania Manufacturer Detail:

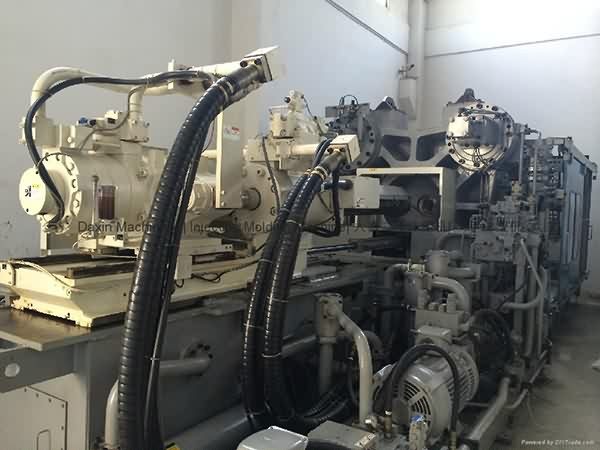

Mitsubishi 1300t used Injection Molding Machine.

Model: 1300MMV-160.

Year of manufactue: 2011.

Tie bar spacing: 1320x1280mm.

Screw diameter: 100mm.

Injection volume: 4540cm^3.

Mould thickness: 700~1200mm.

Clamp stroke: 1800mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Making Plastic – Plastic Injection Moulding

Our target is to consolidate and improve the quality and service of existing products, meanwhile constantly develop new products to meet different customers' demands for Massive Selection for Mitsubishi 1300t Used Injection Molding Machine to Romania Manufacturer, The product will supply to all over the world, such as: Malawi , Surabaya , Algeria , The company attaches great importance to product quality and service quality, based on the business philosophy "good with people, genuine to whole world, your satisfaction is our pursuit". we design products, According to customer's sample and requirements, to meet the needs of the market and offer different customers with personalized service. Our company warmly welcomes friends at home and abroad to visit, to discuss cooperation and seek common development!

Qingdao HEGU wood-plastic machinery Co.,Ltd--WPC decking board/floor making machine.The machine including conical double screw extruder,mold,vacuum sizing platform,hual off device, cutter and stacker.The machine use the Recylced PP/PE and wood powder as the raw material.

Learn about Metal Injection Molding (MIM). Smith Metals is a leader in the industry and here to help. Learn more by visiting https://www.SmithMetals.com.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.