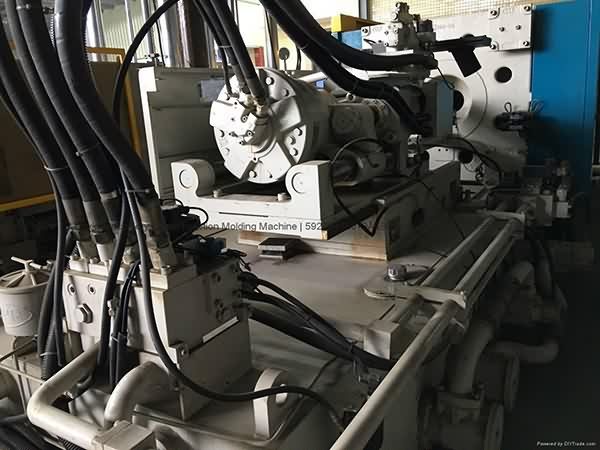

New Arrival China Chuan Lih Fa CLF-650TX used Injection Molding Machine for New Zealand Manufacturer

New Arrival China Chuan Lih Fa CLF-650TX used Injection Molding Machine for New Zealand Manufacturer Detail:

Chuan Lih Fa CLF-650TX Used Injection Molding Machine.

Model: CLF-650TX.

Year: 2008.

Screw diameter: 85mm.

Tie bar spacing: 910x910mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Precision of Plastic Machining

With responsible good quality method, good status and excellent client services, the series of solutions produced by our company are exported to lots of countries and regions for New Arrival China Chuan Lih Fa CLF-650TX used Injection Molding Machine for New Zealand Manufacturer, The product will supply to all over the world, such as: Victoria , St. Petersburg , azerbaijan , We critically promise that we deliver all the customers with the best quality solutions, the most competitive prices and the most prompt delivery. We hope to win a resplendent future for customers and ourselves.

MMC has been supplying cap slitters and TE band inverting machine systems to the closure industry for many years and has advanced the field through innovative machine design.

a) Knotched Knife Slitting Technology

Rotary Cap Slitting machines score the side wall of your plastic closure with arched slitting blade. The slitting blade has intermittent interruptions that will leave a predetermined amount of bridges to hold the Tamper Evident Band to the closure. When the closure is removed from the container for the first time, the bridges break, leaving the band on the neck of the container and demonstrating visual point of purchase tamper evidence to the consumer.

b) Cut-to-post Slitting Technology

A series of ribs are molded into the inner wall of the closure, which will eventually become the bridges that break during closure removal. The closure is rotated against a stationary blade, gradually slicing through the side wall until the blade reaches the molded-in posts.

c) Band Inverter

MMC has launched the CMBF product series to streamline the Tamper Evident Band folding and Band inverting operation. Our unit is a fully automatic multiple head continuous motion machine which is able to fold in the Tamper Evident Band retaining feature allowing the container neck to grip this feature.

For more information, please visit our website

www.mmcpackaging.com

https://www.vsrsuperfinishing.com

HB-superfinishing machine

HB-superfinishing tool

Whatsapp:+86 15866605088

wechat:brady0086

Skype: brady0086

QQ:1156692876

TEL: +86 183 40057108

CELL: +86 15866605088

E-mail:brady0086@hotmail.com

JINAN ZHAOYANG MACHINE CO., LTD

JINAN HUABAO MACHINERY CO., LIMITED

ADD:No.6 Qilihe Road,Jinan,Shandong,China,250001

Contact: Mr. Brady

Great Innovation For Metallic Surface Superfinishing &

Provide Complex Problems Solutions

Superfinishing machine

Great innovation for superfinishing;replace polishing,grinding,rolling;non-abrasive superfinishing.....

The brief:

1. Obtain surface roughness less than Ra0.1 easily;

2. Suitable for different shapes, such as cylindrical, internal, rotor, curved and spherical, axis,etc;

3. Suitable for all kinds of materials, such as carbon steel, aluminum alloy, copper, etc;

4.Suitable for different industries, such as Turbine, Mining machinery, Mechanical valve, Petroleum Machinery, Bearing mechanical, Mold, Paper machinery, Pharmaceutical Machinery centrifuge, Piston rod, Hydraulic cylinder, Helical rod, Metallurgical Machinery, Wind power, Hydropower, Motor.

5.Can be used in all kinds of machine tools, such as lathe, grinding machine, boring machine, milling machine, planning machine, spherical lathe and CNC machine tools, ect;

6. Just one time, improve production efficiency greatly;

7. Components: tool assembly and control-center;

8. Improve the micro-hardness 20%;

9. Improve the wear-resistance;

10. Improve the fatigue life 5 ~100 times;

11. Suitable for the hardness below HRC65;

12. Improve corrosion resistance;

13. It's a nonabrasive process, without abrasive, felt, lapping compounds and hard work.

14.Relieve the residual stress greatly;

15.Long service life of tool and workpieces;

16. It saves time, money and energy;

17. No sawdust and sawdust wastes occurred,no noise and damage to the environment;

18.Easy to operate.

The principle:

According to metallic materials cold plastic deformation in the normal temperature and apply HB-superfinish equipment to superfinish the surface without any abrasive to reach desirable roughness,this process just like ironing clothes.

The process:

Firstly, make the workpiece pre-machining in the general purpose machine, then apply HB-super finishing equipment again, the roughness will reach less than Ra0.1 easily, just like ironing the clothes and a kind of compressive stress created on the surface at the same time, the micro-hardness will be improved more than 20%, the wear resistance will be improved greatly and the life will be improved 5 ~10 times.

The description:

This equipment including two parts, one is cutter, the other is control center,

the cutter is controlled by control center,

there is a unstable ball which made from a special materials on the cutter head,

during process, the ball impacts the surface 30,000 times per second with very little pressure about 2.5N,

the temperature is little higher than the normal temperature,

it's a nonabrassive process, without abrasive, felt, lapping compounds and hardwork,

save time and cost greatly, and very environmental,

it's very different from the rolling, polishing, grinding and other process,

more precisely, it just like ironing the clothes, never remove any materials from the surface.

https://www.vsrsuperfinishing.com

HB-superfinishing machine

Whatsapp:+86 15866605088

wechat:brady0086

Skype: brady0086

QQ:1156692876

TEL: +86 183 40057108

CELL: +86 15866605088

E-mail:brady0086@hotmail.com

JINAN ZHAOYANG MACHINE CO., LIMITED

Former JINAN HUABAO MACHINERY CO., LIMITED

ADD:No.6 Qilihe Road,Jinan,Shandong,China,250001

Contact: Mr. Brady

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!