New Arrival China JSWJ1300EIII used Injection Molding Machine Export to Sierra Leone

New Arrival China JSWJ1300EIII used Injection Molding Machine Export to Sierra Leone Detail:

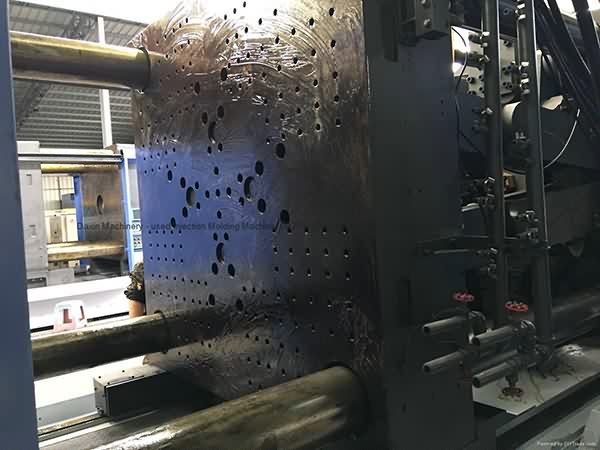

JSW 1600t used injection molding machine.

Model: J1300EIII.

Year: 2008.

Tie bar spacing: 1315x1270mm.

Screw diameter: 120mm.

Machine is in good working condition. Interested customer can visit our warehouse to inspect the machine and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Emergence of Injection Molding in Plastic Industry

We also offer you product sourcing and flight consolidation expert services. We've our personal manufacturing unit and sourcing business. We can offer you virtually every variety of merchandise associated to our item range for New Arrival China JSWJ1300EIII used Injection Molding Machine Export to Sierra Leone, The product will supply to all over the world, such as: Guyana , Georgia , Johannesburg , Please really feel free to send us your requirements and we'll respond to you asap. We have got a professional engineering group to serve for your just about every detailed needs. Cost-free samples could be sent for you personally to understand much more information. In an effort to meet your requires, please really feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd items. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is actually our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

Good day. This is John. From Hong Guan Machinery. With reference to the product offering on your site. May I know if you need a packaging machinery supplies ...

Toshiba Machine’s Table-type Horizontal Boring and Milling Machine BTD-200QH is equipped with a 200mm diameter quill and designed with a remarkably robust and rigid spindle capable of powerful cutting .BTD-200QH is an easy-to-use machine, designed by providing a compact user friendly operator pendant not only for automatic operation but, also for manual functions.

5-axis operation is also available by supplementing a separate rotary table for the machining of complex work pieces.Moreover, with Automatic Pallet Changer and incorporating a newly developed electrical interphase for the rotary table ultimately leading to an extremely effective unmanned machine process with no operator intervention.Toshiba Machine shall continue to present new Technologies for the future and contribute to the development of our customer’s products to achieve efficient and profitable productivity.

Table-type Horizontal Boring and Milling Machine BTD-200QH

Toshiba Machine Official Hompage (Machine Tools)

https://www.toshiba-machine.co.jp/en/product/machinetool/lineup/b/btd200qh.html

Main features

1. Easy-to-operate compact pendant for manual machining operations

Most sophisticated CNC system TOSNUC 999

Wide table withstand heavy load and allows easy set-up

2. High rigidity bed supports the entire machine

3. B-axis drive mechanism provides high-speed and high-accuracy machining

4. 5000min-1 spindle with high-speed and high-torque specifications (option)

5. NC rotary milling operation (option)

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!