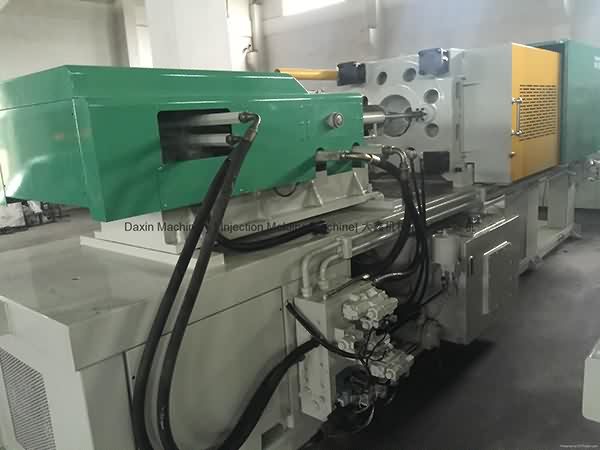

New Fashion Design for Chen Hsong Super Master SM250TS used Injection Molding Machine for Lebanon Factories

New Fashion Design for Chen Hsong Super Master SM250TS used Injection Molding Machine for Lebanon Factories Detail:

Taiwan Chen Hsong Super Master 250t used Injection Molding Machine for sale

Youtube Video: https://youtu.be/W0oWFc3ZjF4

Model: SM250TS.

Year: 2007..

Screw diameter: 45mm. .

Tie bar spacing: 620x620mm.

High precision. Very good running condition. Interested customer is welcome to visit our warehouse to inspect the machine and power it on to test run.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Making Plastic – Plastic Injection Moulding

We now have many fantastic staff members customers superior at advertising, QC, and working with varieties of troublesome problem within the generation system for New Fashion Design for Chen Hsong Super Master SM250TS used Injection Molding Machine for Lebanon Factories, The product will supply to all over the world, such as: Philippines , Latvia , Boston , All our staffs believe that: Quality builds today and service creates future. We know that good quality and the best service are the only way for us to achieve our customers and to achieve ourselves too. We welcome customers all over the word to contact us for future business relationships. Our products are the best. Once Selected, Perfect Forever!

Website: https://redctv.com Facebook: https://www.facebook.com/RedCTelevision Twitter: https://twitter.com/redctv https://twitter.com/redctvcom ...

Giken Sakata (S) Limited - Japanese

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly