New Fashion Design for Haitian 160t used Injection Molding Machine to USA Importers

New Fashion Design for Haitian 160t used Injection Molding Machine to USA Importers Detail:

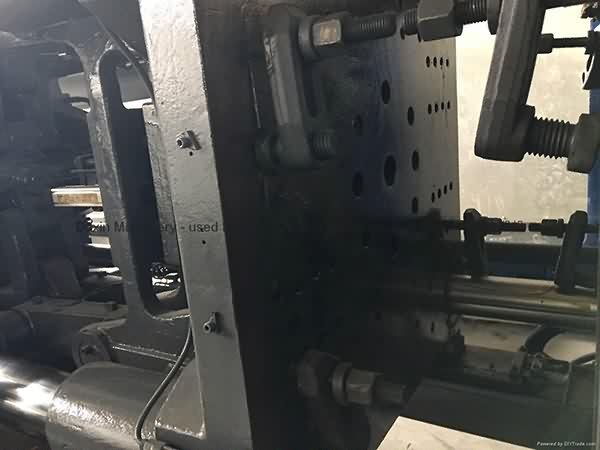

Haitian 160t used Injection Molding Machine

Model: SA1600/540v.

Year: 2010.

Screw: B-D38.

Tie bar spacing: 460mm.

Very good working condition. Interested buyer can visit our warehouse to inspect them and test them running under power.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Precision of Plastic Machining

Our rewards are reduce selling prices,dynamic revenue team,specialized QC,sturdy factories,superior quality services for New Fashion Design for Haitian 160t used Injection Molding Machine to USA Importers, The product will supply to all over the world, such as: Mexico , Serbia , Juventus , Our stock have valued 8 million dollar , you can find the competitive parts within short delivery time. Our company is not only your partner in business, but also our company is your assistant in the coming corporation.

Automatic Bottle Making Machine

Manual Spacer Bar Round Curve Bender,Manual Spacer Bar Round Bender,Spacer Bar Curve Bending Machine,Spacer Bar Curve Bender,Aluminum Spacer Bar Curve Bending Machine,Aluminum Spacer Bar Curve Bender,Spacer Bar Round Bender,Spacer Bar Round Bending Machine,Aluminum Spacer Bar Bender,Aluminum Spacer Bar Bending Machine,Manual Spacer Bar Round Bender,Semi-Automatic Spacer Bar Round Bender,Manual Spacer Bar Round Bending Machine,Manual Aluminum Spacer Bar Bender,Manual Aluminum Spacer Bar Bending Machine,Semi-Automatic Spacer Bar Round Bending Machine,Semi-Automatic Aluminum Spacer Bar Bender,Semi-Automatic Aluminum Spacer Bar Bending Machine,Manual Spacer Bar Curve Bending Machine,Manual Spacer Bar Curve Bender,Manual Aluminum Spacer Bar Curve Bending Machine,Manual Aluminum Spacer Bar Curve Bender,Manual Spacer Bar Curve Bending Machine,Semi-Automatic Spacer Bar Curve Bender,Semi-Automatic Aluminum Spacer Bar Curve Bending Machine,Semi-Automatic Aluminum Spacer Bar Curve Bender,Semi-Automatic Spacer Bar Curve Bending Machine,Semi-Automatic Spacer Bar Curve Bender,Semi-Automatic Aluminum Spacer Bar Curve Bending Machine,Semi-Automatic Aluminum Spacer Bar Curve Bender

If any interested in it,pls send emails to sales@saintbestgroup.com or saintbestgroup@163.com or add Skype:allenszj for direct conversation.

URL:www.saintbestgroup.com www.doubleglazingequipment.com www.digitaluvprinter.com www.shuntaitech.com

Whatsapp/Wechat:+86-186-6042-5078

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.