New Fashion Design for Niigata 180t used All-electric Injection Molding Machine to Sydney Manufacturer

New Fashion Design for Niigata 180t used All-electric Injection Molding Machine to Sydney Manufacturer Detail:

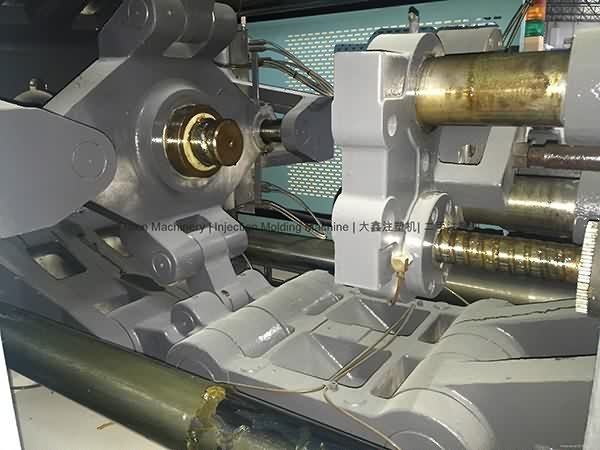

Niigata 180t All-electric used Injection Molding Machine

Youtube Video: https://youtu.be/gdXRtoSqbW0

Model: MD180S-IV.

Year: 2006.

Injection Speed: 300mm/s.

Screw diameter: 35mm.

Tie bar spacing: 510x510mm.

Machines are in good running condition. Two units available. Interested customers are welcome to visit our warehouse to inspect and test machines running.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

The Precision of Plastic Machining

We persistently execute our spirit of ''Innovation bringing growth, Highly-quality making sure subsistence, Administration marketing reward, Credit history attracting clients for New Fashion Design for Niigata 180t used All-electric Injection Molding Machine to Sydney Manufacturer, The product will supply to all over the world, such as: Kuwait , South Africa , Saudi Arabia , They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a should for you of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we are going to possess a vibrant prospect and to be distributed all over the world within the years to come.

CCM continuous compression moulding hydraulic press for plastic cap manufacturing via the extrusion of dry-blend granulated compounds (i.e. HDPE, PP). The new CCM 48 SC has a cycle time of just 1.8 seconds. https://goo.gl/pnAxO9

Water Damage Restoration? West Islip, NY Deer Park, NY Call (631) 888-6080 24/7, Call Now (613) 888-6080, or go to our website for more details. Open 24/7 365 days

https://westbabylonrestorationpros.com/

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.