New Fashion Design for Niigata 450t All-electric used Injection Molding Machine for Zimbabwe Factory

New Fashion Design for Niigata 450t All-electric used Injection Molding Machine for Zimbabwe Factory Detail:

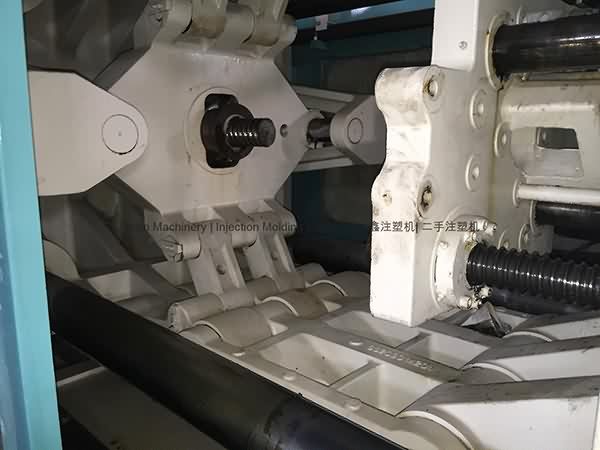

Niigata 450t All-Electric used Injection Molding Machine

Youtube Video: https://youtu.be/wHoMpY6lKng

Model: MD450S-IV.

Year: 2007.

Screw diameter: 82mm.

Tie bar spacing:820x820mm.

Injection Speed: 150mm/s.

Two units available. Interested customer is welcome to visit our warehouse to test machines running. Our warehouse is at Shenzhen, China (very near Hongkong and Guanzhou) .

Visit us after Chinaplas or Canton Fair!

Daxin Machinery

-Over 200 units of used injection molding machines in stock

-All can be inspected in the same warehouse under one roof

-All can be powered on for test-run in working condition

sales@daxin88.com / daxin88@hotmail.com

Skype: daxin-machinery / www.daxin88.com

Mobile: +8613509620296 (whatsapp) / +6596479097 (WeChat)

Follow Daxin Machinery: Facebook, Twitter, Google+, LinkedIn, Youtube.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

Making Plastic – Plastic Injection Moulding

We emphasize progress and introduce new merchandise into the market each and every year for New Fashion Design for Niigata 450t All-electric used Injection Molding Machine for Zimbabwe Factory, The product will supply to all over the world, such as: Kuala Lumpur , Marseille , Dubai , Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our products have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

more information available: www.uniplastico.com

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!