Newly Arrival JSWJ150EIII used Injection Molding Machine for UK Factory

Newly Arrival JSWJ150EIII used Injection Molding Machine for UK Factory Detail:

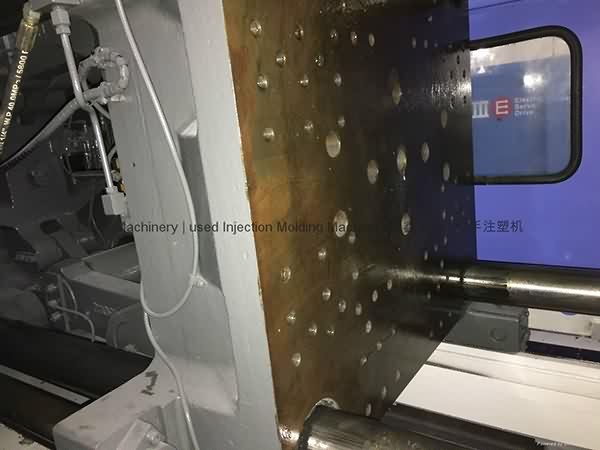

JSWJ150EII used Injection Molding Machine.

Model: JSWJ150EIII.

Year: 2006.

Screw diameter: 46mm.

Tie bar spacing: 510x510mm.

Machine is in very good running condition. Interested customer please visit our warehouse to inspect the machine and test it running under power.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

The Emergence of Injection Molding in Plastic Industry

We're committed to furnishing easy,time-saving and money-saving one-stop purchasing support of consumer for Newly Arrival JSWJ150EIII used Injection Molding Machine for UK Factory, The product will supply to all over the world, such as: Venezuela , Madrid , Madrid , Our products are mainly exported to Europe, Africa, America, the Middle East and Southeast Asia and other countries and regions. We have enjoyed a great reputation among our customers for quality products and good services.We would make friends with businessmen from at home and abroad, following the purpose of "Quality First, Reputation First, the Best Services."

Milacron VL600-76, 600ton, 95 ounce, CAMAC VEL controls, new 1994. for sale by owner 586.228.2100.

Used 1000 Ton Engel Injection Molding Machine, 160oz, Model ES 7050/1000AH/CC100, 1999 Vintage Tonnage...........................1000 ton Shot ...

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.