OEM Customized Haitian 250t (servo) used Injection Molding Machine to Kyrgyzstan Manufacturer

OEM Customized Haitian 250t (servo) used Injection Molding Machine to Kyrgyzstan Manufacturer Detail:

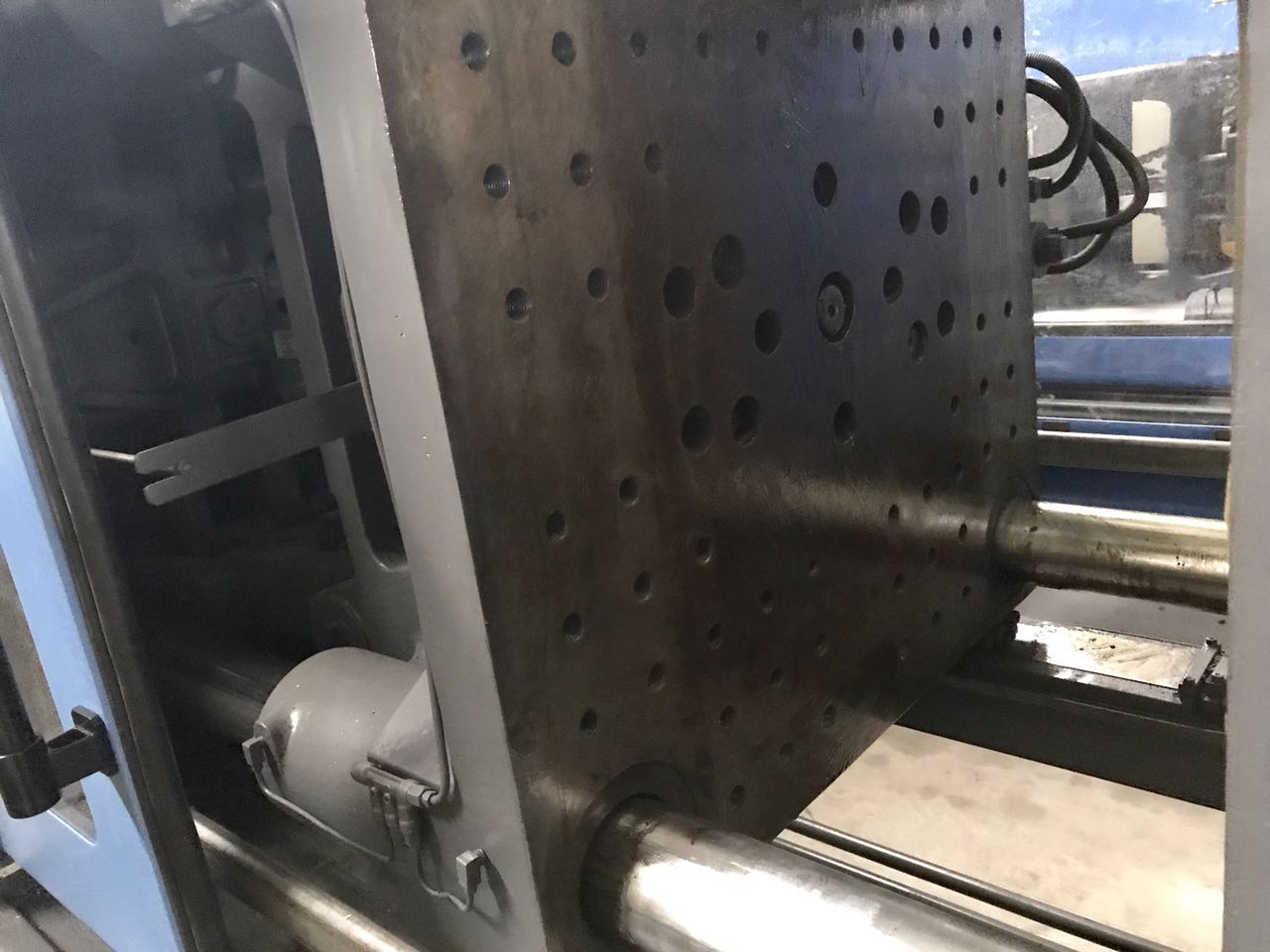

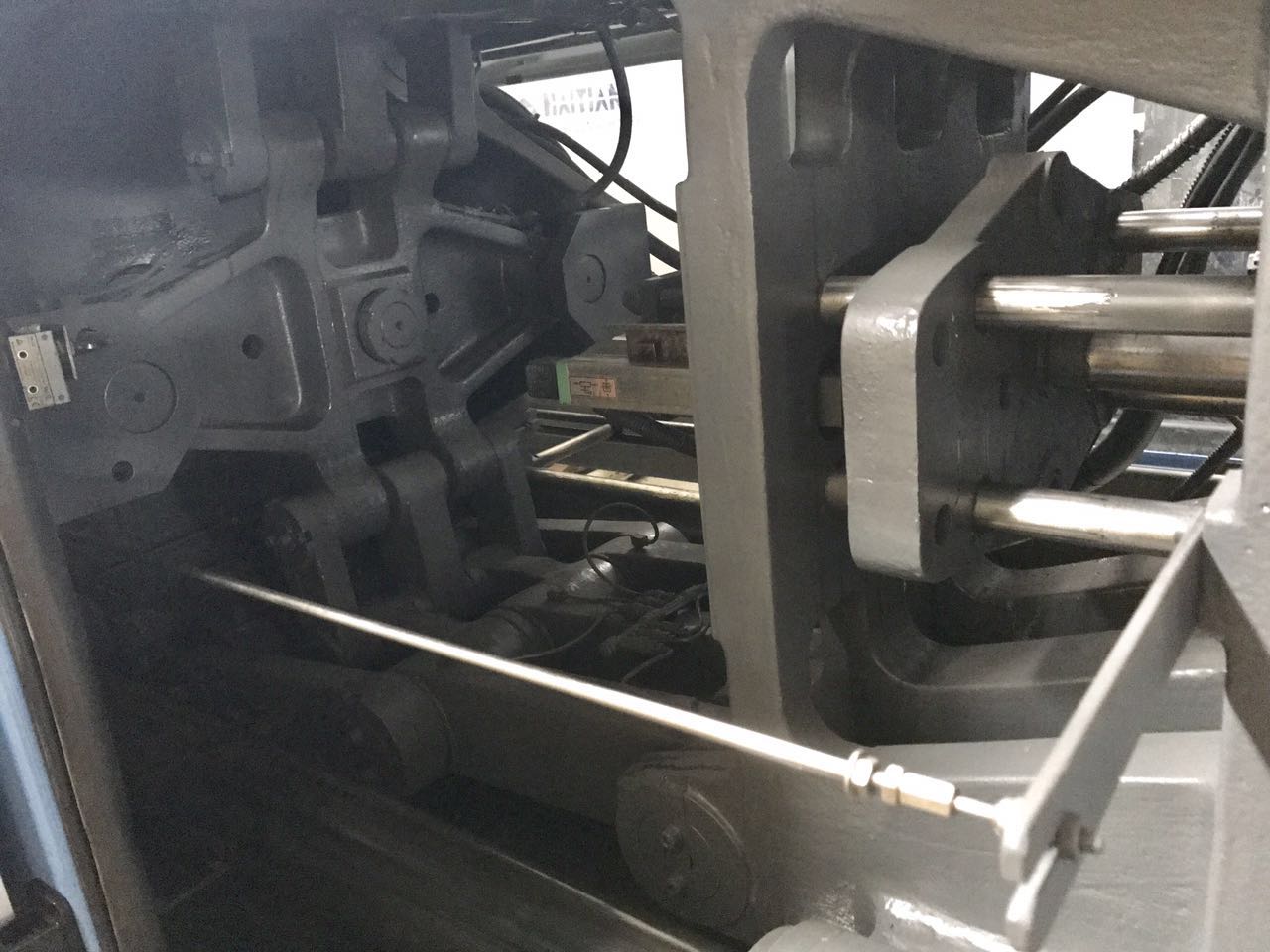

Haitian 250t (servo) used Injection Molding Machine.

Model: MA250.

Year: 2012.

Tie bar spacing: 580x580mm.

Good working condition.

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

How Importers And Exporters Can Benefit From The Canton Fair

The corporate upholds the philosophy of "Be No.1 in excellent, be rooted on credit rating and trustworthiness for growth", will keep on to serve outdated and new clients from home and abroad whole-heatedly for OEM Customized Haitian 250t (servo) used Injection Molding Machine to Kyrgyzstan Manufacturer, The product will supply to all over the world, such as: Bahamas , Seychelles , Luxemburg , Our team knows well the market demands in different countries, and is capable of supplying suitable quality products and solutions at the best prices to different markets. Our company has already set up a experienced, creative and responsible team to develop clients with the multi-win principle.

Call David Macdonald for more info on 03 9706 8066 or email sales@appliedmachinery.com.au.

How to programme a Williams Blast Chiller for a soft chill cycle.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.