OEM Factory for 95 Ton 130 Ton 170 Ton Small Automatic Pet Preform Plastic Injection Molding Machine

Assume full obligation to meet all calls for of our clients; realize steady advancements by marketing the advancement of our clients; turn out to be the final permanent cooperative partner of clientele and maximize the interests of clients for OEM Factory for 95 Ton 130 Ton 170 Ton Small Automatic Pet Preform Plastic Injection Molding Machine, We are now seeking forward to even bigger cooperation with overseas buyers dependant on mutual rewards. Should you be interested in almost any of our solutions, be sure to come to feel no cost to call us for additional particulars.

Assume full obligation to meet all calls for of our clients; realize steady advancements by marketing the advancement of our clients; turn out to be the final permanent cooperative partner of clientele and maximize the interests of clients for 95 Ton 130 Ton 170 Ton Small Pet Preform Plastic Injection Molding Machine, Pet Preform Injection Moulding Machine, Small Automatic Pet Preform Making Machine, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade solutions in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We have been willing to cooperate with business friends from at home and abroad and create a great future together.

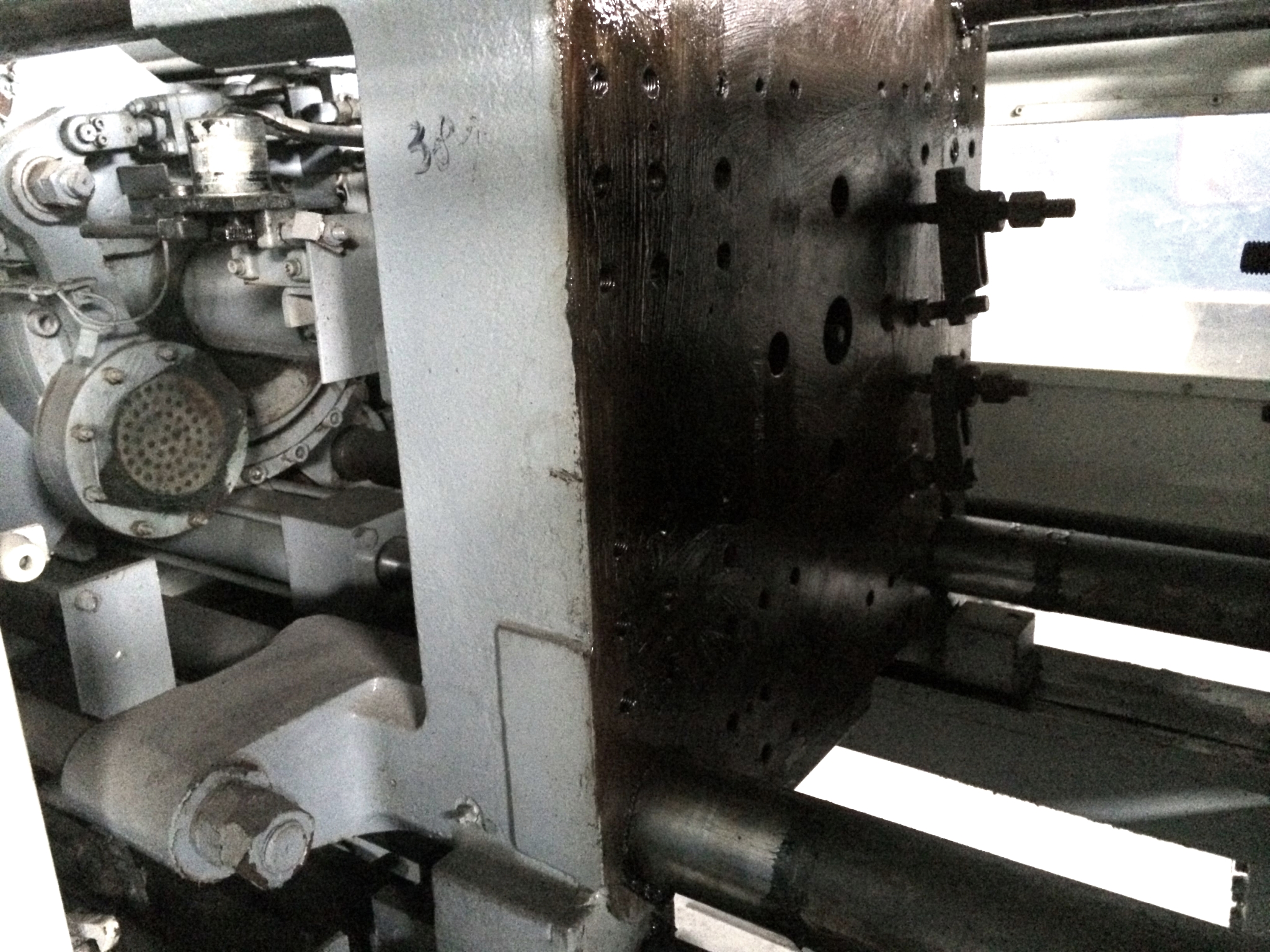

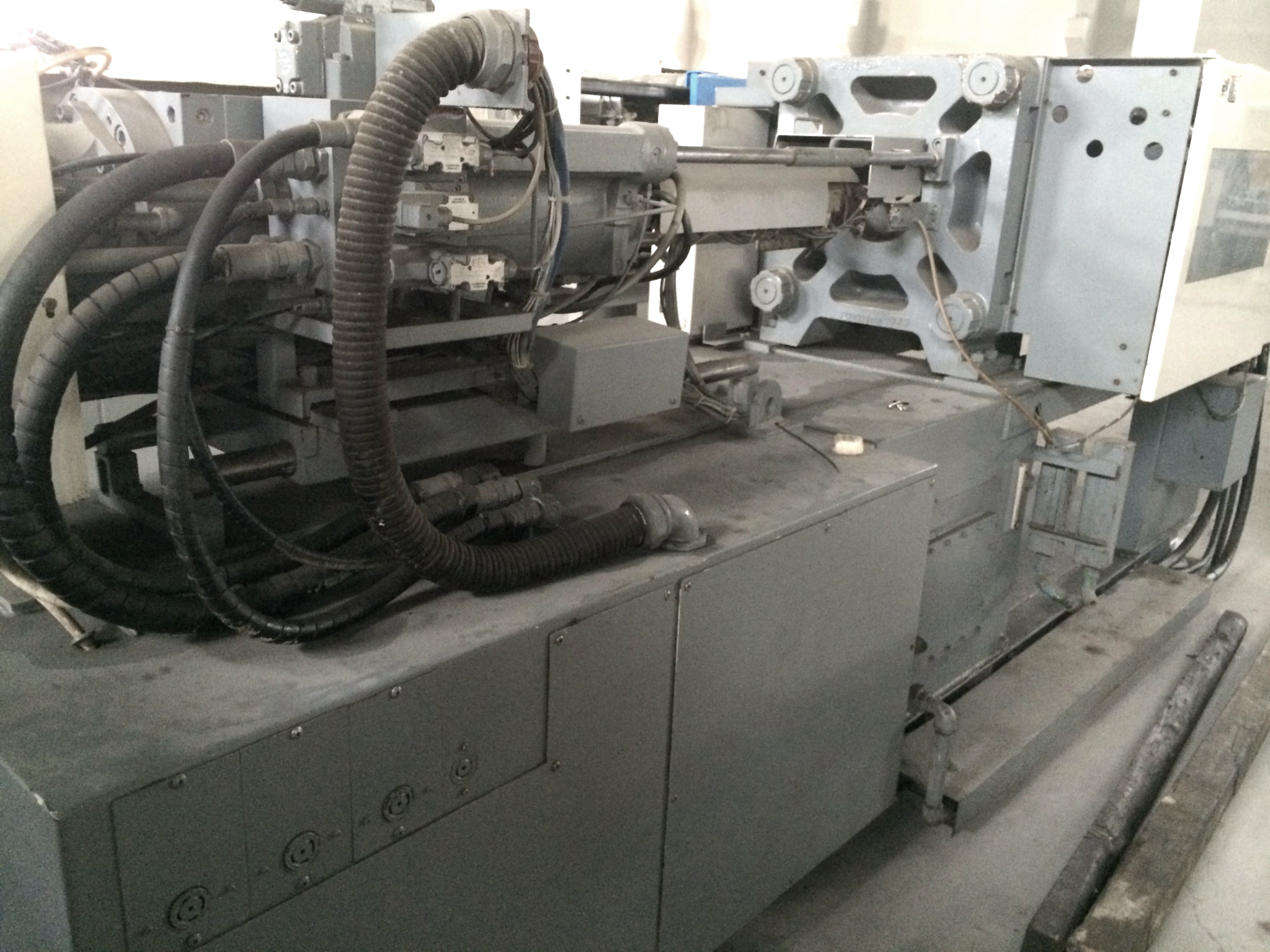

Sumitomo used plastic injection molding machine

Model: SH125A

Tie bar distance: 460x460mm.

Screw diamter: 36mm.

Manufacture year: 2000

Machine is in good running condition. Interested buyers are welcome to inspect machine anytime in our warehouse.

Why choose Daxin?

- Wide range of machines: Over 200 machines (20-2000t) in 10000 sqm warehouse (Largest collection of Japanese machines in China)

- Rich experience in export: one-stop solution including dismantling of machines, loading, moving, custom clearing (many agents cannot clear custom for used machines), shipment, assembling and commissioning of machines.

- All machines can be powered on for test-run. All machines can be viewed under one roof in our warehouse.

- Post-sale support: providing spare parts, commissioning machine, inputting program, repairing PCB boards or other machine parts

- Quality assured: All machines parts are checked thoroughly, including pumps, toggle, screw, barrel, oil seals, ball bearing, platen.etc.

- Any defective parts are repaired or replaced if beyond repair.

- Have exported to more than 30 countries : South East Asia, South Asia, Australia , Middle East, Africa, South America, Central America.

Product Image

www.borum.as

Ultra Linemarking from Autralia have purchased their first Borum second hand machine in 2016.

The BM 250-2 is supplied with the Borum thermoplastic extruder for applying flat and profiled markings.

See what second hand machines we have available on www.borum.as or https://goo.gl/W1qsi0

Injection moulding (injection molding in the USA) is a manufacturing process for producing parts by injecting material into a mould. Injection moulding can be performed with a host of materials, including metals, (for which the process is called diecasting), glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed, and forced into a mould cavity, where it cools and hardens to the configuration of the cavity