OEM Factory for Chen Hsong Super Master SM250TS used Injection Molding Machine for St. Petersburg Importers

OEM Factory for Chen Hsong Super Master SM250TS used Injection Molding Machine for St. Petersburg Importers Detail:

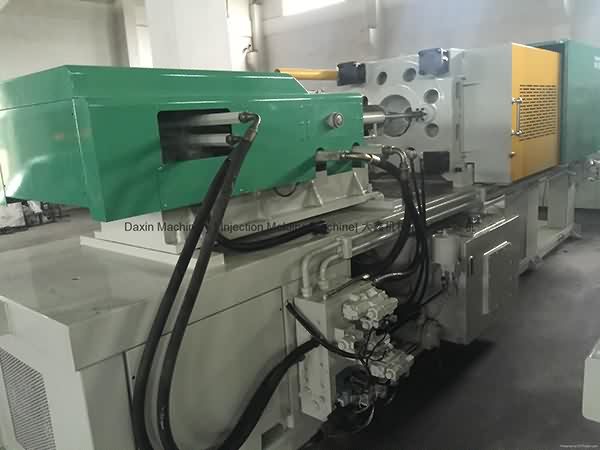

Taiwan Chen Hsong Super Master 250t used Injection Molding Machine for sale

Youtube Video: https://youtu.be/W0oWFc3ZjF4

Model: SM250TS.

Year: 2007..

Screw diameter: 45mm. .

Tie bar spacing: 620x620mm.

High precision. Very good running condition. Interested customer is welcome to visit our warehouse to inspect the machine and power it on to test run.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Precision of Plastic Machining

We not only will try our greatest to supply outstanding services to every shopper, but also are ready to receive any suggestion offered by our buyers for OEM Factory for Chen Hsong Super Master SM250TS used Injection Molding Machine for St. Petersburg Importers, The product will supply to all over the world, such as: Hongkong , Swiss , Florence , Our company is an international supplier on this kind of merchandise. We offer an amazing selection of high-quality products. Our goal is to delight you with our distinctive collection of mindful products while providing value and excellent service. Our mission is simple: To provide the best products and service to our customers at the lowest prices possible.

Professional manufacturer of Recycling Equipment and Material Recovery Facility. Especially expertize in PET Recycling Machine, PET Recycling Equipment, PET Recycling Line, PET Recycling Plant, PET Recycling Machinery, PET Bottle Recycling Machine

This is the PET Recycling Line we installed in China.

1000kg/hr

A grade output

output chips/flakes are ready for synthetic fiber

IV: 0.7~0.8

Specification specified briefly as below:

PET Recycling Line -- A Grade output × 1000kg/hr

PET Recycling Line Length (measurement): 67M

PET Recycling Line Witdh (measurement) : 6.8M

PET Recycling Line Hight (measurement) : 4.5M

PET Recycling Line input capability: 1200~1500kg/hr

PET Recycling Line output capacity: 1000kg/hr (guarantee)

PET Recycling Line Power consumption: 282.5KW

PET Recycling Line Total Water consumption: 30M^3

PET Recycling Line Delivery time : 100Days

My first time in China. I was enlightened to see this.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.