OEM Factory for Haitian 250t (servo) used Injection Molding Machine Export to Buenos Aires

OEM Factory for Haitian 250t (servo) used Injection Molding Machine Export to Buenos Aires Detail:

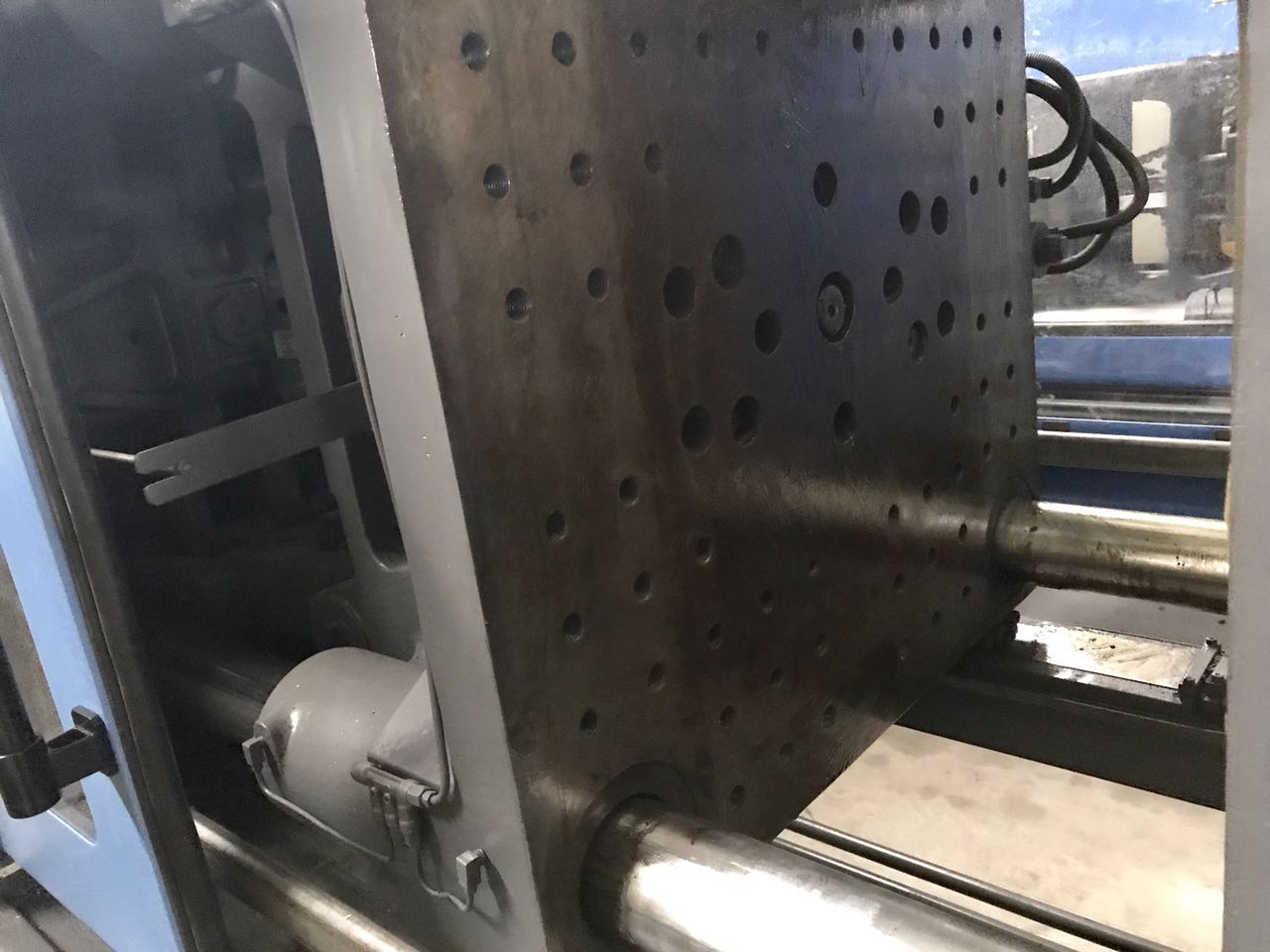

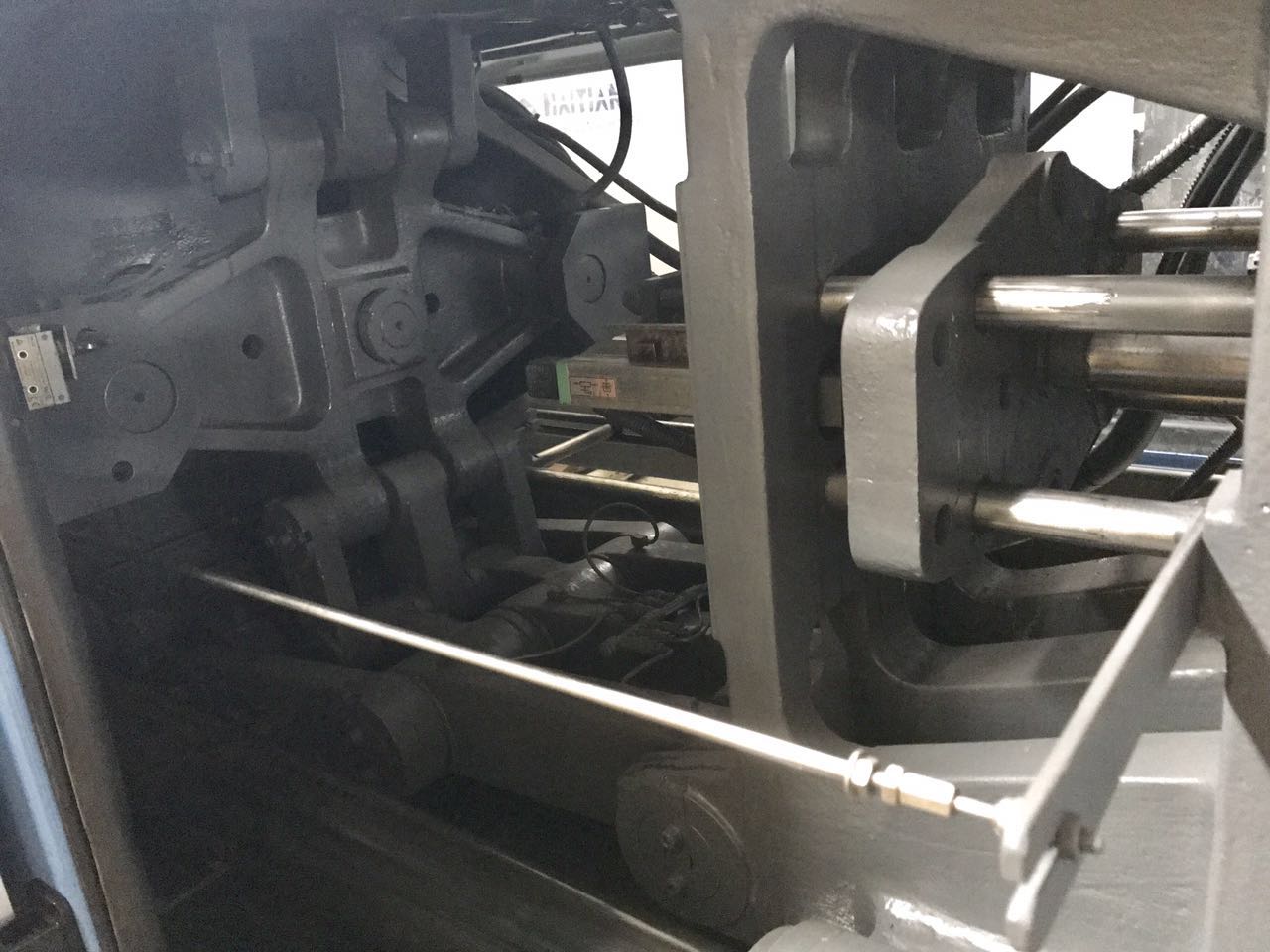

Haitian 250t (servo) used Injection Molding Machine.

Model: MA250.

Year: 2012.

Tie bar spacing: 580x580mm.

Good working condition.

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

How Importers And Exporters Can Benefit From The Canton Fair

Our growth depends around the superior machines, exceptional talents and consistently strengthened technology forces for OEM Factory for Haitian 250t (servo) used Injection Molding Machine Export to Buenos Aires, The product will supply to all over the world, such as: Armenia , Belgium , Turkey , Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

A new hybrid 3D printing technique developed at the Wyss Institute at Harvard University, Harvard’s John A. Paulson School of Engineering and Applied Sciences, and the Air Force Research Laboratory combines stretchable conductive inks and electronic components into flexible, durable wearable devices that move with the body and offer increased programmability. Credit: Wyss Institute at Harvard University

To learn more, please visit: https://wyss.harvard.edu/low-cost-wearables-manufactured-by-hybrid-3d-printing

https://elitemachinerysystems.com/injection_molding_machinery.php?prod_id=1119 500 ton Cincinnati Milacron Injection Molding Machine For Sale. VH500-54 ...

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.