OEM Factory for Sonly U438ts Injection Molding Machine Small Plastic Moulding Servo Motor Machine

Our pursuit and company intention is usually to "Always fulfill our purchaser requirements". We go on to acquire and layout excellent high quality products for both our previous and new consumers and realize a win-win prospect for our customers too as us for OEM Factory for Sonly U438ts Injection Molding Machine Small Plastic Moulding Servo Motor Machine, We sincerely stay up for hearing from you. Give us a chance to show you our professionalism and passion. We've been sincerely welcome superior mates from numerous circles at dwelling and overseas come to cooperate!

Our pursuit and company intention is usually to "Always fulfill our purchaser requirements". We go on to acquire and layout excellent high quality products for both our previous and new consumers and realize a win-win prospect for our customers too as us for Plastic Box Injection Moulding Machine, Plastic Hanger Injection Moulding Machine, Plastic Injection Molding Machine, Our staffs are adhering to the "Integrity-based and Interactive Development" spirit, and the tenet of "First-class Quality with Excellent Service". According to the needs of every customer, we give customized & personalized services to help customers achieve their goals successfully. Welcome clients from home and abroad to call and inquire!

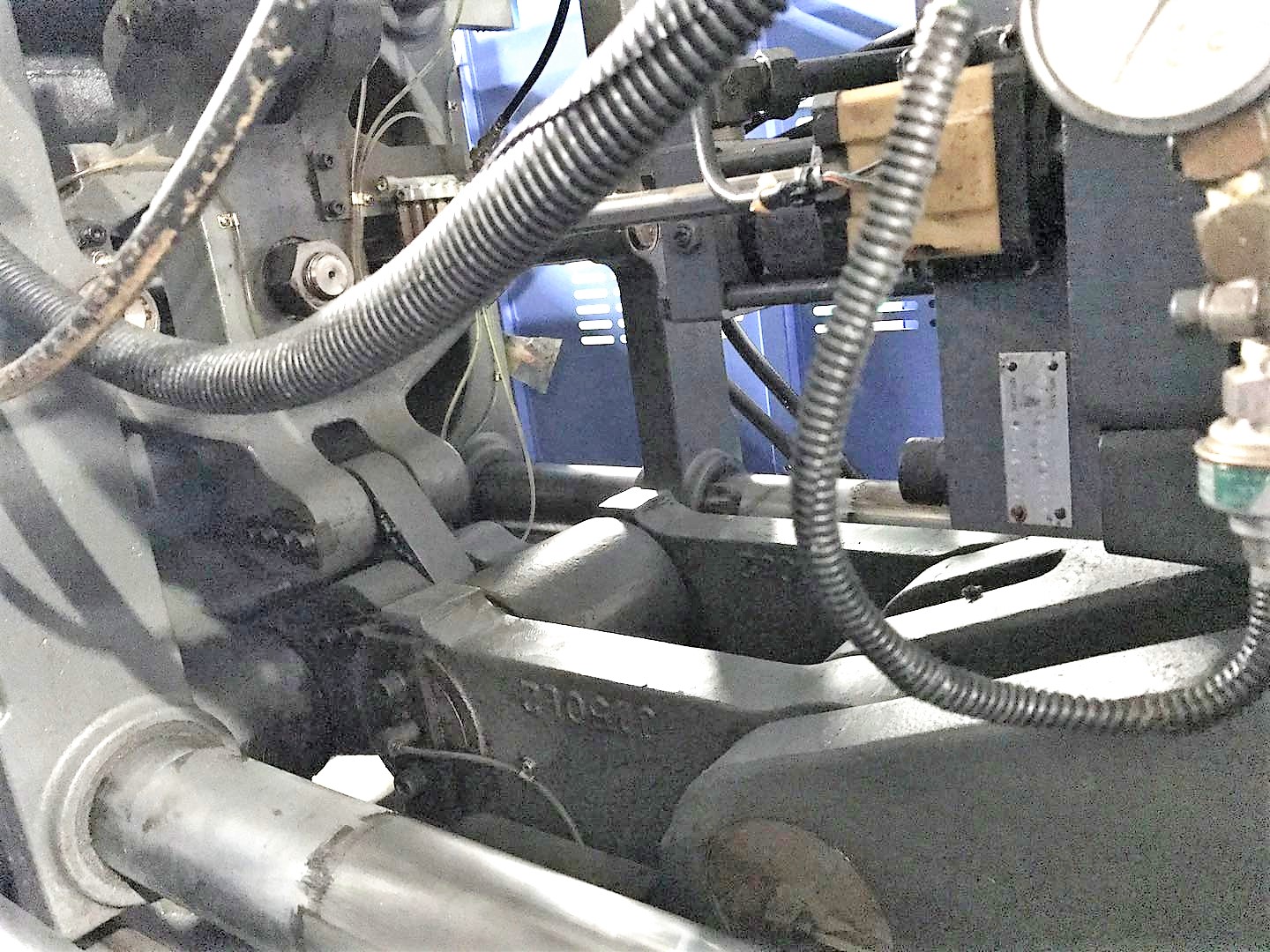

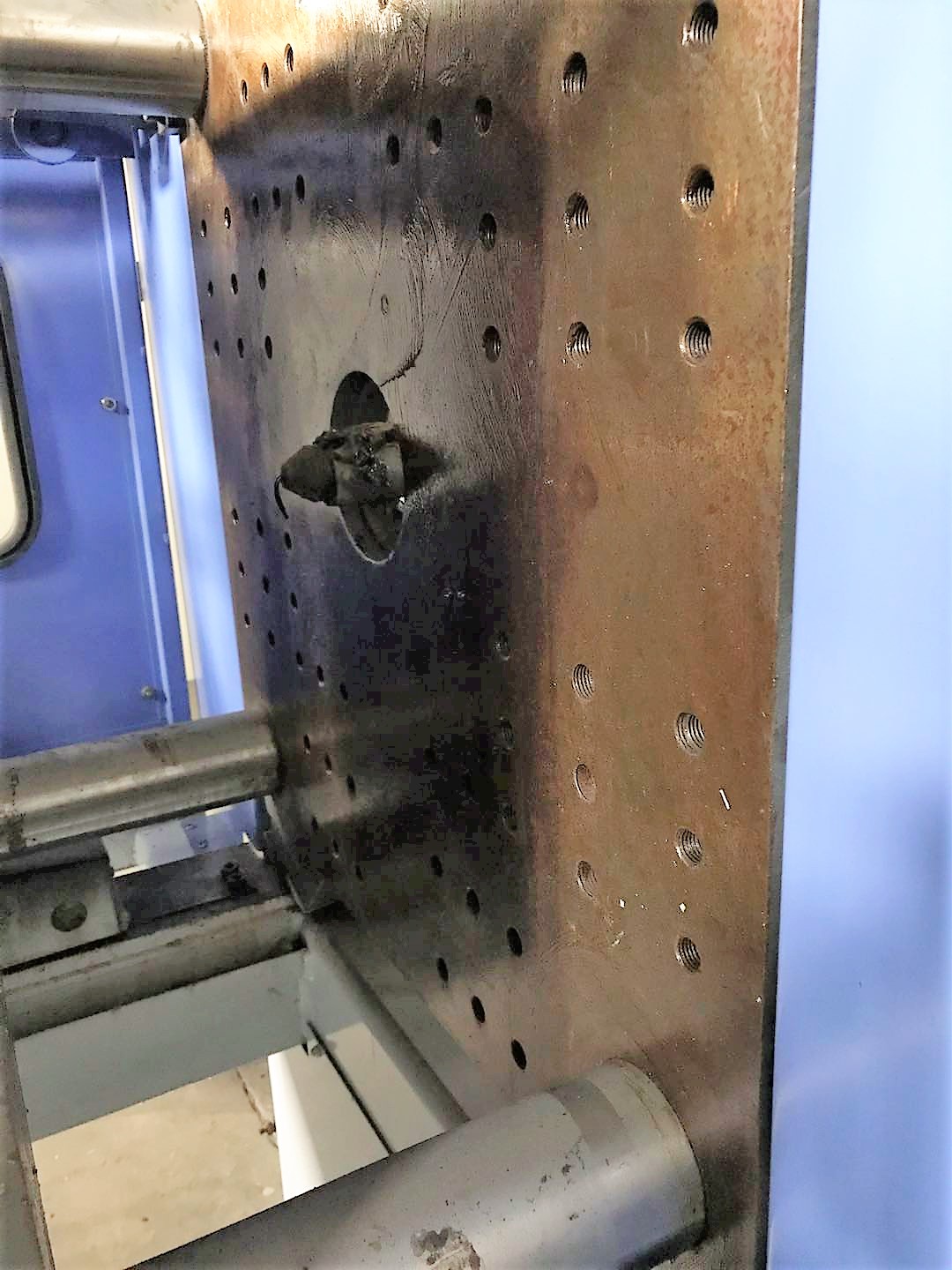

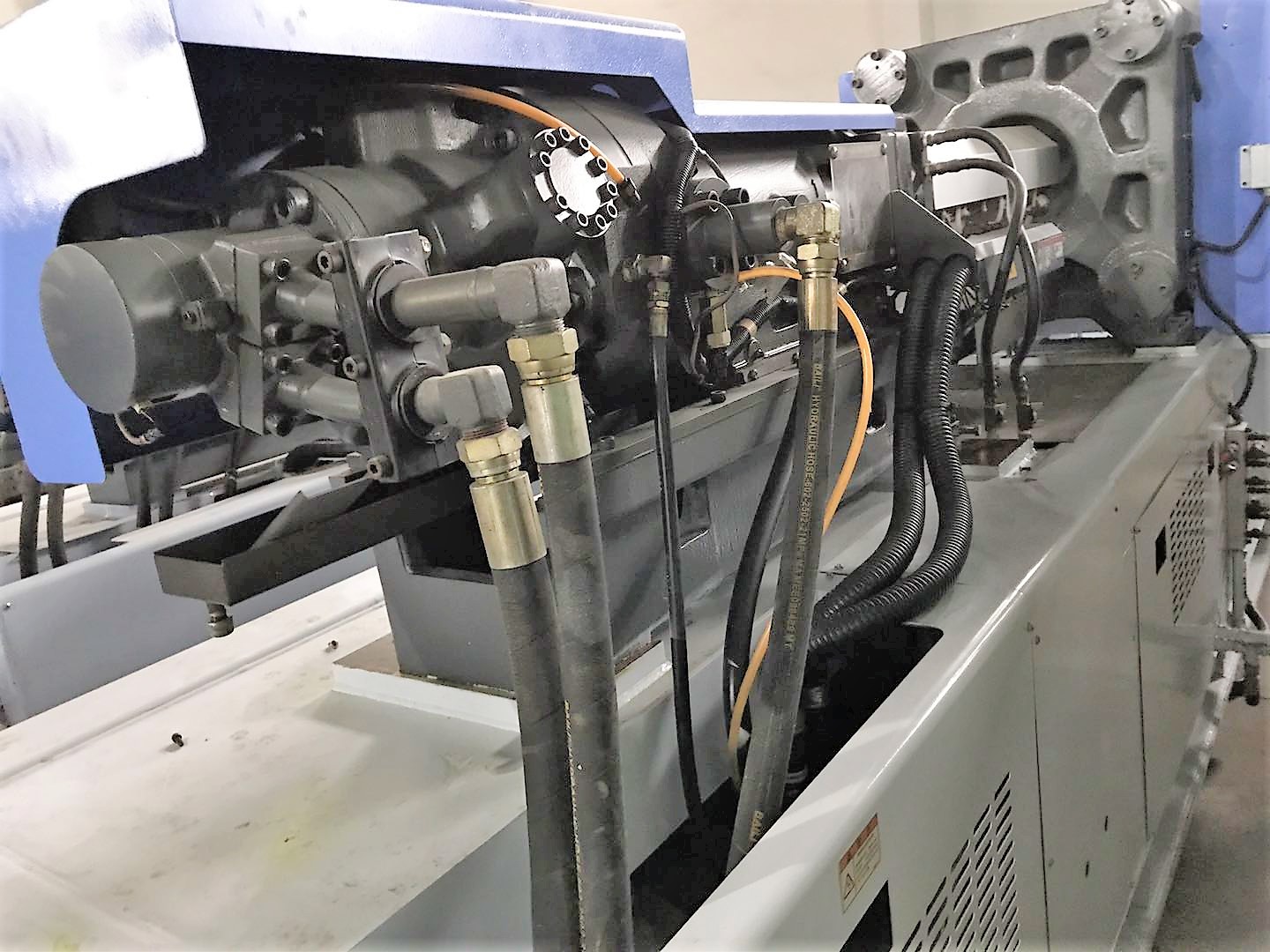

JSWJ150EII used Injection Molding Machine.

Video: https://youtu.be/QGdc1stqJCI

Model: JSWJ150EIII.

Year: 2006.

Screw diameter: 46mm.

Tie bar spacing: 510x510mm.

Machine is in very good running condition. Interested customer please visit our warehouse to inspect the machine and test it running under power.

Why choose Daxin?

- Wide range of machines: Over 200 machines (20-2000t) in 10000 sqm warehouse (Largest collection of Japanese machines in China)

- Rich experience in export: one-stop solution including dismantling of machines, loading, moving, custom clearing (many agents cannot clear custom for used machines), shipment, assembling and commissioning of machines.

- All machines can be powered on for test-run. All machines can be viewed under one roof in our warehouse.

- Post-sale support: providing spare parts, commissioning machine, inputting program, repairing PCB boards or other machine parts

- Quality assured: All machines parts are checked thoroughly, including pumps, toggle, screw, barrel, oil seals, ball bearing, platen.etc.

- Any defective parts are repaired or replaced if beyond repair.

- Have exported to more than 30 countries : South East Asia, South Asia, Australia , Middle East, Africa, South America, Central America.

Product Image

Water Damage Restoration? Lindenhurst, NY Call (631) 888-6080 24/7, Call Now (613) 888-6080, or go to our website for more details. Open 24 Hours

https://westbabylonrestorationpros.com/

TPU Granules plant/factory

Extrusion Molding (TPU Extrusion Material, Thermoplastic PU Extrusion Material, TPU Extrusion Resin):

● Air Bag, Cable & Wire, Belt, Film & Sheet and other extrusions.

● Hose Material: Air Tube, Hose, Fire Hose, Cable & Wire.

● Sheet Material: Film, Sheet, Conveyor Belt.

Injection Molding:

General Grade (TPU Injection Material, Thermoplastic PU Injection Material, TPU Injection Resin (polyester base)):

Shoes Material: Shoe Soles, Shoes Decorations, Air Bag, Label, Oil Bag.

Industrial Parts: Snow Boots, Buckle, Aminal ID Tags, Mining Screens, O-ring.

Wheel: Load Wheel, Skates Wheel, Trolley Wheel.

High Wear Resis. & High hydrolysis Resis (TPU Injection Material, Thermoplastic PU Injection Material, TPU Injection Resin (polyether base & Polycaprolactone Base)):

Shoes Material: Shoe Soles, Shoes Decorations, Air Bag, Label, Oil Bag.

Industrial Parts: Snow Boots, Buckle, Aminal ID Tags, Mining Screens, O-ring.

Wheel: Load Wheel, Skates Wheel, Trolley Wheel.

Low Temperature Resis. & Transparent Grade (TPU Injection Material, Thermoplastic PU Injection Resin (Transparent Grade & Low Temperature Resistance)):

Shoes Material: Shoe Soles, Shoes Decorations, Air Bag, Label, Oil Bag.

Industrial Parts: Snow Boots, Buckle, Aminal ID Tags, Mining Screens, O-ring.

Wheel: Load Wheel, Skates Wheel, Trolley Wheel.

Calender Molding (TPU Calender Material, Thermoplastic PU Calender Material, TPU Calender Resin):

Calendering -- Process sheet, Calendering -- Process Film.

TPU for Ink (Thermoplastic Resin for Ink):

Screen Printing, Transfer Coating for all kindly of material for shoe and textile industries and others.

Contact information:

TAIWAN PU CORPORATION

TEL:886-2-2299-1666

FAX:886-2-2299-1888

E-MAIL: pu@taiwanpu.com

WEBSITE: www.taiwanpu.com

TPUCO TPU Injection Material/TPU Extrusion Material:

Taiwan PU Corporation, known as TPUCO, is a professional manufacturer and a world-class factory of TPU Injection Material.

For more than 25 years, TPUCO has created a trustworthy worldwide reputation due to excellent service and high-quality polyurethane products.

With TPUCO’s leading producing and processing technologies, TPUCO can manufacture various kinds of TPU Injection Material according to client’s requirement.

Each step of producing TPU Injection Material is carefully calculated by production line engineers.

From raw material selecting to final product selecting, TPUCO has chemical engineers and quality control technicians to make sure the TPU Injection Materials fit client’s need of physical properties.

Therefore, TPUCO assures customers of the reliability and the top quality of the TPU Injection Material.

In addition, TPUCO does not only manufacture excellent quality of TPU Injection Material, but also develop and customize similar new PU Raw Material.

TPUCO believes in “innovation, creativity, and incentive for improvement.”

With a strong and experienced technical support team, TPUCO is constantly developing new kinds of TPU Injection Material and other PU finished products for closer cooperation with customers and higher leading position in polyurethane industry.

As a world-class factory and supplier for both PU finished products and PU raw materials, according to client’s usage and require properties of the TPU Injection Material, TPUCO is able to design TPU Injection Material from PU raw material, to producing and processing methods, and then to PU finished products.

Moreover, for special property requirement, TPUCO’s more than 25-year experience allows TPUCO to know what chemical additives are the right and the best fit for customers’ TPU Injection Material. For instance, by choosing and adding the right flame retardants, TPUCO is able to produce ECO-friendly fire resistant TPU Injection Material, which lower fire-related accident rate and increase end-users’ safety.

Developed by TPUCO’s global research and product engineering team, TPUCO TPU Injection Material deliver excellent wear characteristics.

In addition to excellent abrasion resistance, the specially engineered polyurethane compound is able to make TPUCO TPU Injection Material to have High hydrolysis Resis.

TPUCO TPU Injection Material is also ideal for low-operating-temperature production environments. In other words, TPUCO TPU Injection Material has excellent operational characteristics in low temperature applications.

TPUCO TPU Injection Material offer exceptional mechanical properties, which yield outstanding life potential and improvements in damage resistance. Specifically, TPUCO TPU Injection Material’s superior tensile, tear, elongation, and resilience properties deliver extended life potential and resistance to damage.

TPUCO TPU Injection Material is available in extended hardness range from 70-95 Shore A.

If you are looking for TPU Injection Material, Taiwan PU Corporation is your best choice of polyurethane manufacturer.