OEM Factory for Toshiba IS650GT Used Injection Molding Machine for New York Factory

OEM Factory for Toshiba IS650GT Used Injection Molding Machine for New York Factory Detail:

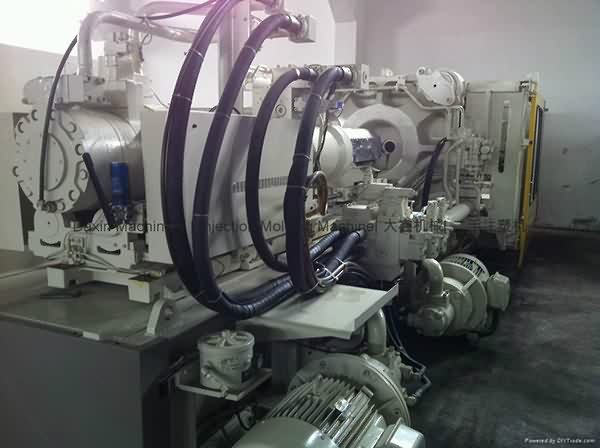

Toshiba 650t used Injection Molding Machine.

Video: https://youtu.be/60tsjjKGmX8

Model: IS650GT-59A.

Screw diameter: 90/95mm.

Tie bar spacing: 980x980mm.

Year: 2004/2006.

Controller type: V10.

Machines are in good working condition. A few units available. Our warehouse is located at ShenZhen of China, very near HongKong and GuangZhou. Interested buyer is welcome to visit our warehouse during Chinaplas to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

The Precision of Plastic Machining

The corporation upholds the philosophy of "Be No.1 in high quality, be rooted on credit rating and trustworthiness for growth", will continue to serve outdated and new consumers from home and overseas whole-heatedly for OEM Factory for Toshiba IS650GT Used Injection Molding Machine for New York Factory, The product will supply to all over the world, such as: South Africa , Algeria , Toronto , Now, with the development of internet, and the trend of internationalization, we have decided to extend business to overseas market. With the propose of bringing more profits to oversea customers by providing directly abroad. So we have changed our mind, from home to abroad, hope to give our customers more profit, and looking forward to more chance to make business.

Gia cong ép nhựa giá rẻ toàn quốc số lượng ít 100- 1000 Sp theo yêu cầu 0932668186 Tuấn.

Woojin Plaimm PR Film

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.