OEM manufacturer Chuan Lih Fa CLF-650TX used Injection Molding Machine to Egypt Factories

OEM manufacturer Chuan Lih Fa CLF-650TX used Injection Molding Machine to Egypt Factories Detail:

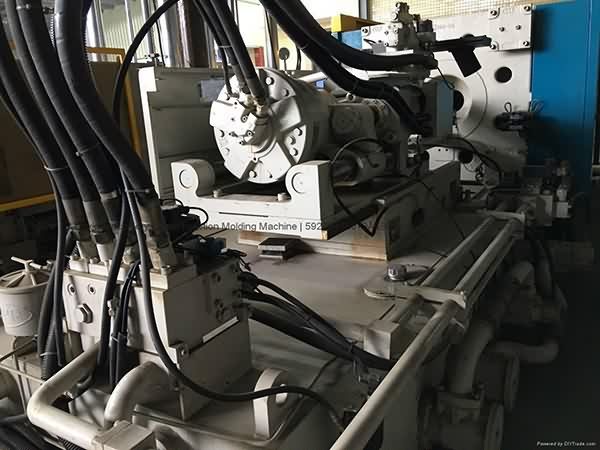

Chuan Lih Fa CLF-650TX Used Injection Molding Machine.

Model: CLF-650TX.

Year: 2008.

Screw diameter: 85mm.

Tie bar spacing: 910x910mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Making Plastic – Plastic Injection Moulding

With reliable good quality system, great standing and perfect consumer support, the series of products and solutions produced by our organization are exported to quite a few countries and regions for OEM manufacturer Chuan Lih Fa CLF-650TX used Injection Molding Machine to Egypt Factories, The product will supply to all over the world, such as: Turkey , Liverpool , Southampton , Our advanced equipment, excellent quality management, research and development ability make our price down. The price we offering may not be the lowest, but we guarantee it is absolutely competitive! Welcome to contact us immediately for future business relationship and mutual success!

2,500 Ton Danly Stamping Press For Sale For Sale 616-200-4308, For up to date detials stock visit our website https://d3r5f9xr0rb0d5.cloudfront.net/ We buy and sell presses and feeders. If you have equipment for sale please contact us.

https://youtube.com/watch?v=K7vPBH7bKxQ

INJECTION MOULDING MACHINE FOR THERMOPLASTICS

PRESSE AD INIEZIONE PER TERMOPLASTICI

www.plasticmetal.it

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.