OEM Manufacturer Niigata 180t used All-electric Injection Molding Machine for Mauritius Factory

OEM Manufacturer Niigata 180t used All-electric Injection Molding Machine for Mauritius Factory Detail:

Niigata 180t All-electric used Injection Molding Machine

Youtube Video: https://youtu.be/gdXRtoSqbW0

Model: MD180S-IV.

Year: 2006.

Injection Speed: 300mm/s.

Screw diameter: 35mm.

Tie bar spacing: 510x510mm.

Machines are in good running condition. Two units available. Interested customers are welcome to visit our warehouse to inspect and test machines running.

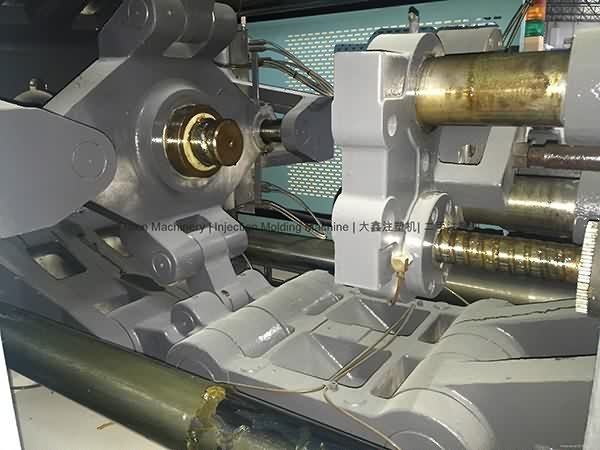

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

How Importers And Exporters Can Benefit From The Canton Fair

Our merchandise are commonly identified and dependable by end users and will meet continually altering financial and social desires for OEM Manufacturer Niigata 180t used All-electric Injection Molding Machine for Mauritius Factory, The product will supply to all over the world, such as: Saudi Arabia , Brunei , Palestine , Our company's main items are widely used all over the world; 80% of our products and solutions exported to the United States, Japan, Europe and other markets. All stuff sincerely welcome guests come to visit our factory.

Manufacturers of Water Taps in Coimbatore, Tamilnadu, India. Visit www.leotaps.com for more taps and fittings.

Milacron VL600-76, 600ton, 95 ounce, CAMAC VEL controls, new 1994. for sale by owner 586.228.2100.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.