OEM manufacturer Niigata 180t used All-electric Injection Molding Machine Supply to Paraguay

OEM manufacturer Niigata 180t used All-electric Injection Molding Machine Supply to Paraguay Detail:

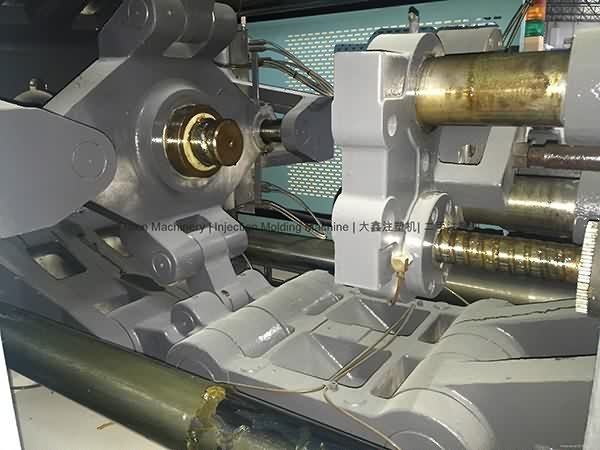

Niigata 180t All-electric used Injection Molding Machine

Youtube Video: https://youtu.be/gdXRtoSqbW0

Model: MD180S-IV.

Year: 2006.

Injection Speed: 300mm/s.

Screw diameter: 35mm.

Tie bar spacing: 510x510mm.

Machines are in good running condition. Two units available. Interested customers are welcome to visit our warehouse to inspect and test machines running.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Making Plastic – Plastic Injection Moulding

Together with the "Client-Oriented" enterprise philosophy, a arduous good quality control technique, sophisticated producing equipment and a sturdy R&D staff, we generally offer superior quality merchandise, superb solutions and aggressive rates for OEM manufacturer Niigata 180t used All-electric Injection Molding Machine Supply to Paraguay, The product will supply to all over the world, such as: South Korea , Portugal , Argentina , Custom orders are acceptable with different quality grade and customer's especial design. We are looking forward to establish the good and successful cooperation in business with long terms from the customers of all over the world.

Chris Duke from Motorz TV https://www.motorz.tv shows you how to a nitrous oxide kit from Nitrous Express on a 2008 Ford Mustang GT (S197).

SUBSCRIBE FOR MORE: https://www.youtube.com/subscription_center?add_user=motorztv

Show notes: https://www.motorz.tv/nitrous-oxide/

Website: https://www.motorz.tv/

Facebook: https://www.facebook.com/motorztv

Twitter: https://twitter.com/motorz/

Veja o estande da Toshiba Machine na feira K 2016 em Düsseldorf.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.