OEM Manufacturer Niigata 180t used All-electric Injection Molding Machine to kazakhstan Manufacturers

OEM Manufacturer Niigata 180t used All-electric Injection Molding Machine to kazakhstan Manufacturers Detail:

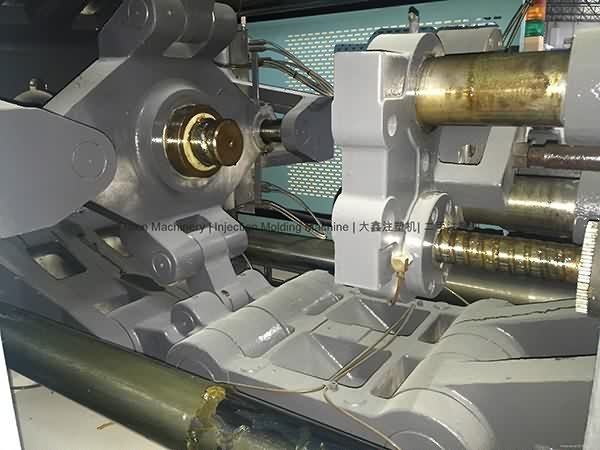

Niigata 180t All-electric used Injection Molding Machine

Youtube Video: https://youtu.be/gdXRtoSqbW0

Model: MD180S-IV.

Year: 2006.

Injection Speed: 300mm/s.

Screw diameter: 35mm.

Tie bar spacing: 510x510mm.

Machines are in good running condition. Two units available. Interested customers are welcome to visit our warehouse to inspect and test machines running.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

The Emergence of Injection Molding in Plastic Industry

Our commission is always to provide our customers and clientele with best quality and aggressive portable digital products for OEM Manufacturer Niigata 180t used All-electric Injection Molding Machine to kazakhstan Manufacturers, The product will supply to all over the world, such as: Bangladesh , Wellington , Romania , We will not only continuously introduce technical guidance of experts from both home and abroad, but also develop the new and advanced products constantly to satisfactorily meet the needs of our clients all over the world.

I am lily from China Darin Machinry. If you are interested our machine. Please do not hesitate to contact me at any time.

Looking forward to your inquiry.

Lily

JINAN DARIN MACHINERY CO., LTD

Skype:darinlilyliu

QQ: 103386119

Wechat:smile520lily

Whatsapp/Viber/Mobile: 0086 15063392887

E-mail: darin10@darin.cn

Facebook:liulili_7981530@126.com

Web: www.darin.cn or www.packingmachine.org

Pet Treats Injection Moulding Machine is special machinery for producing pet snacks. With such machine, various shapes can be made, such as hedgehog, crocodile, dog, bone, pork ears, barrel, etc. The shapes are very lovely and it is a ideal encouragement to dogs and cats while they learn a new action or do well in some exercises and games. Also, we can provide different recipes to meet various market demands.

1.Pet Treats Injection Moulding Machine comes with user-friendly microprocessor controller with these following features.

2.Equipped with servo motor to realize higher efficiency and lower consumption.

3.Dust, oil proof and colorful touch switch control panel.

4.El display of pressure, speed, time and distance for each motion.

5.Shut-down device with 100 presets mold data memory.

6.Equipped with 4 stages injection, 3 stages holding pressure and 3 stages back pressure.

7.PID barrel temperature control: temperature abnormal & electrical wire disconnection alarm.

8.SSR-solid state temperature controller.

9.Screw cold start protection.

10.Abnormal shot detection.

11.Output quantity and packaging quantity preset.

12.Clamping, injection and ejection (option), and carriage action (option) by linear potentiometer.

13.Screw rotating speed read-out.

14.Security code function to avoid missing data or careless changing.

15.Super low pressure clamping ensures security of user, and maintains lifespan of machine efficiently.

Since the establishment in 1963, we have been developing businesses as a machine and edge tool manufacturer not only in Japan but also overseas. Our company credo "Trust" means that we are committed to acquiring technological capabilities that allow us to earn the trust of users, making products that can "respond to the trust", and fostering human resources to grow to be a company that "can gain the trust". We use special steel of a Japanese blast furnace manufacturer as raw materials for various types of blades. As of 2013, we had No.1 production volume of grass cutting blades in Japan, and manufacture and sell the high-quality products that are fully produced domestically. We also deal in a variety of products for applications in agriculture, gardening, construction and others, and have a track record of exports to the world leading brush cutter manufacturers. We take all possible measures to ensure safety as well as sharpness or durability, and are strictly checking the quality of products.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.