OEM Supply Niigata 180t used All-electric Injection Molding Machine to Slovak Republic Factories

OEM Supply Niigata 180t used All-electric Injection Molding Machine to Slovak Republic Factories Detail:

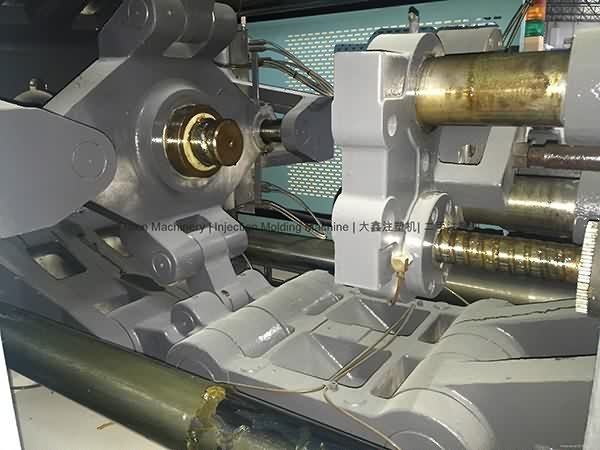

Niigata 180t All-electric used Injection Molding Machine

Youtube Video: https://youtu.be/gdXRtoSqbW0

Model: MD180S-IV.

Year: 2006.

Injection Speed: 300mm/s.

Screw diameter: 35mm.

Tie bar spacing: 510x510mm.

Machines are in good running condition. Two units available. Interested customers are welcome to visit our warehouse to inspect and test machines running.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Making Plastic – Plastic Injection Moulding

We keep on with our business spirit of "Quality, Performance, Innovation and Integrity". We goal to create much more worth for our customers with our rich resources, state-of-the-art machinery, experienced workers and exceptional providers for OEM Supply Niigata 180t used All-electric Injection Molding Machine to Slovak Republic Factories, The product will supply to all over the world, such as: Auckland , Lebanon , Hamburg , We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

How to programme a Williams Blast Chiller for a soft chill cycle.

https://www.perfumeoils.com/index.php?p=product&id=1386.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.