OEM Supply Sumitomo 130t All-Electric used Injection Modling Machine for Amman Factory

OEM Supply Sumitomo 130t All-Electric used Injection Modling Machine for Amman Factory Detail:

Sumitomo 130t All-Electric Used Injection Molding Machine

Video: https://youtu.be/dh8sN_uCzjU

Model: SE130EV-C360HP.

Year: 2013.

Screw diameter: 25/28mm.

Injection Speed: 1000mm/s.

Tie bar spacing: 510x510mm.

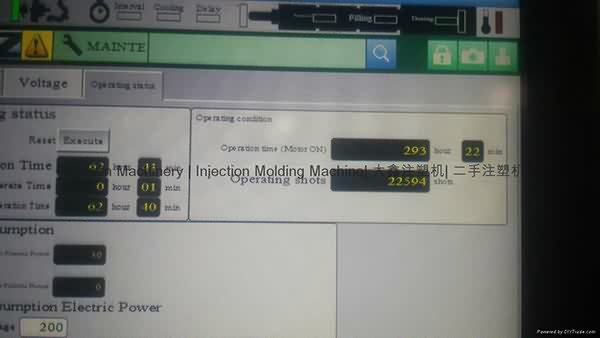

3 units. Machines are in very good and new running condition with less than 300 running hours. They are ultra high speed. Interested customers can visit our warehouse to inspect and test run machines.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

Plastic Injection Molding: Past, Present and Future

With our loaded encounter and considerate services, we have now been recognized as a trustworthy supplier for lots of worldwide consumers for OEM Supply Sumitomo 130t All-Electric used Injection Modling Machine for Amman Factory, The product will supply to all over the world, such as: Benin , Serbia , Guatemala , Our stock have valued 8 million dollar , you can find the competitive parts within short delivery time. Our company is not only your partner in business, but also our company is your assistant in the coming corporation.

Surgical Bandage Are The Products Manufactured From White Bleached Cotton Gauge Cloth Of Suitable Quality. Surgical Bandage Come In Roll Form In ...

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.