OEM/ODM China Haitian 1300t (servo) used Injection Molding Machine Wholesale to Turkmenistan

OEM/ODM China Haitian 1300t (servo) used Injection Molding Machine Wholesale to Turkmenistan Detail:

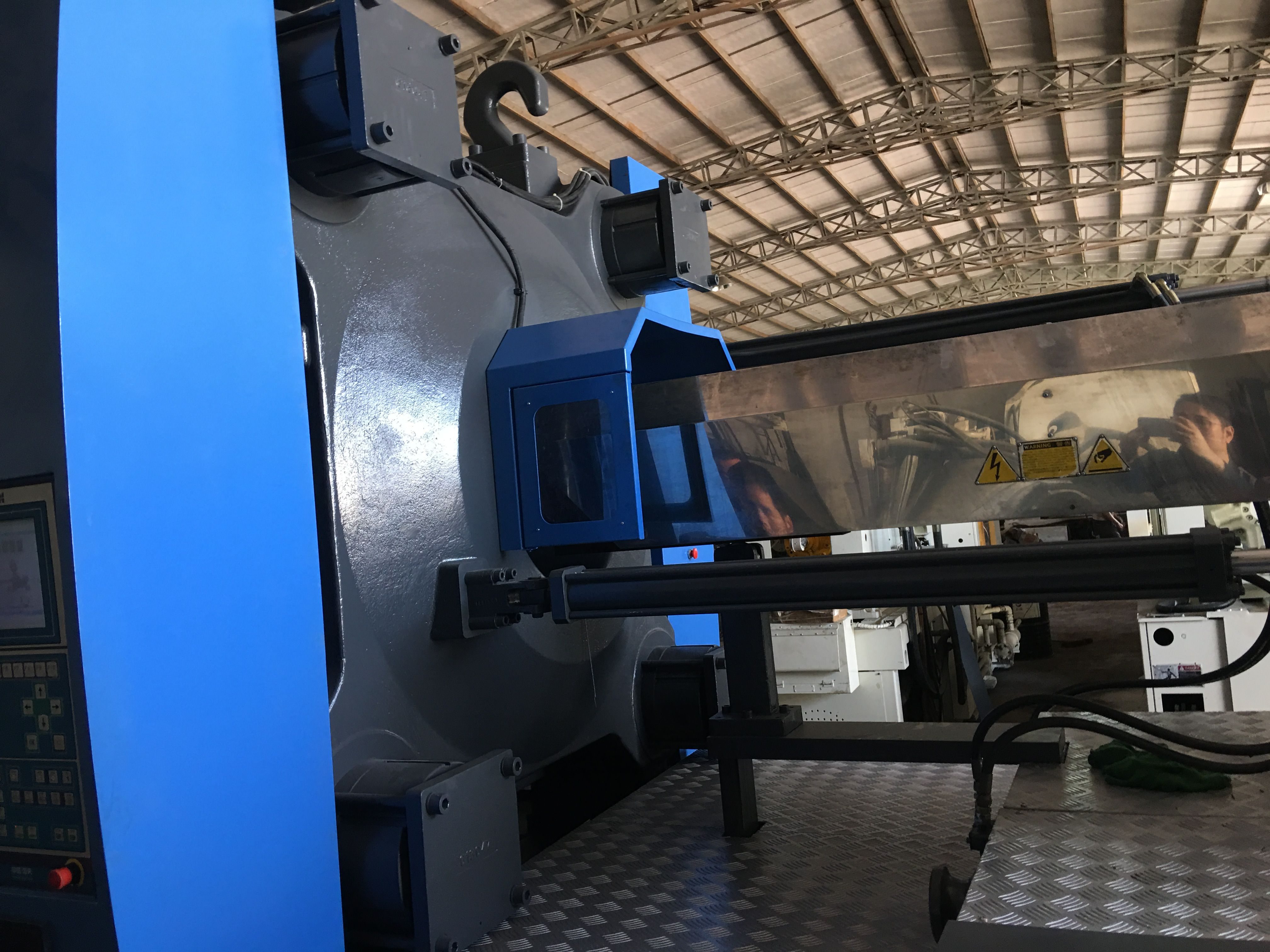

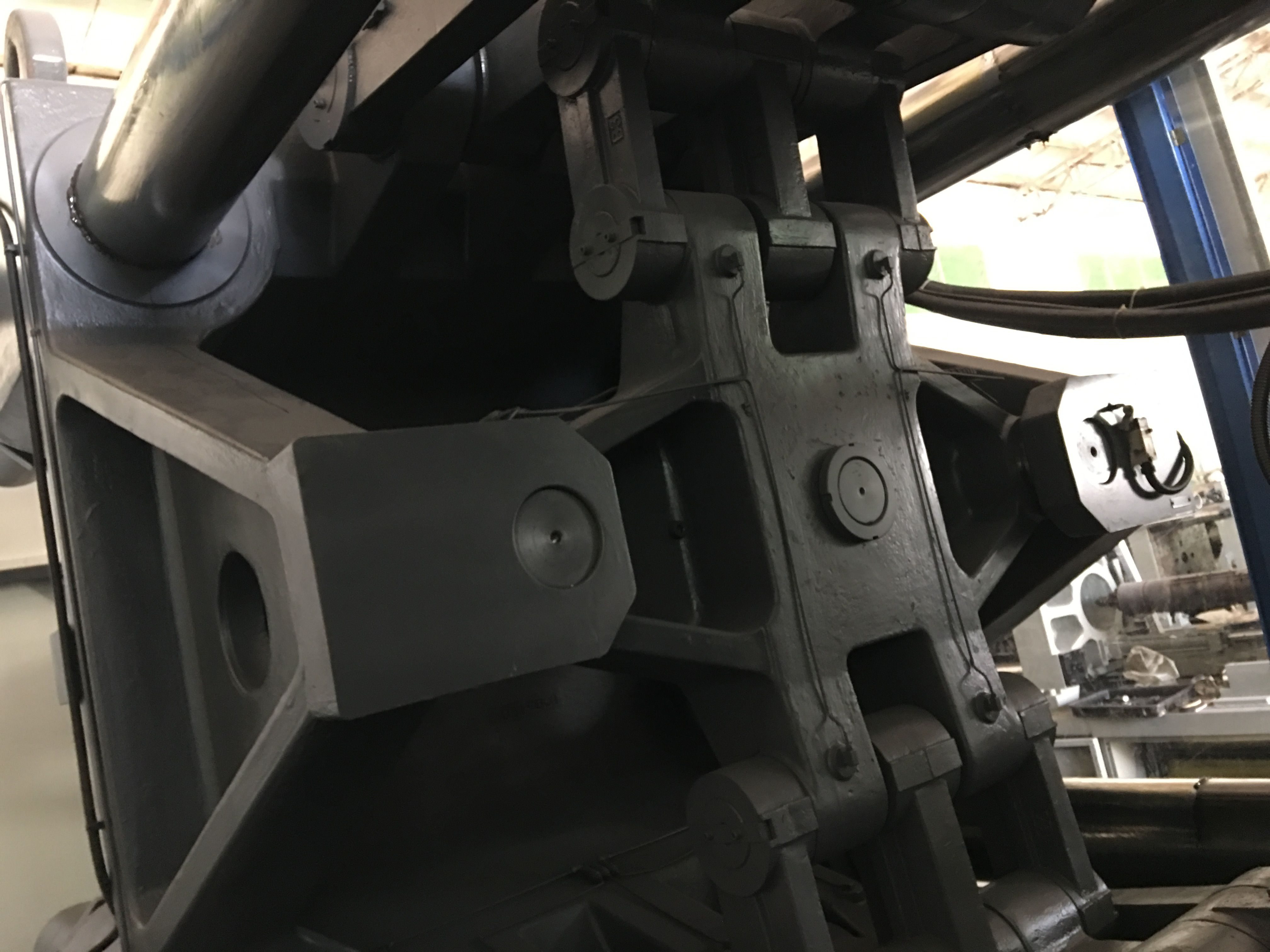

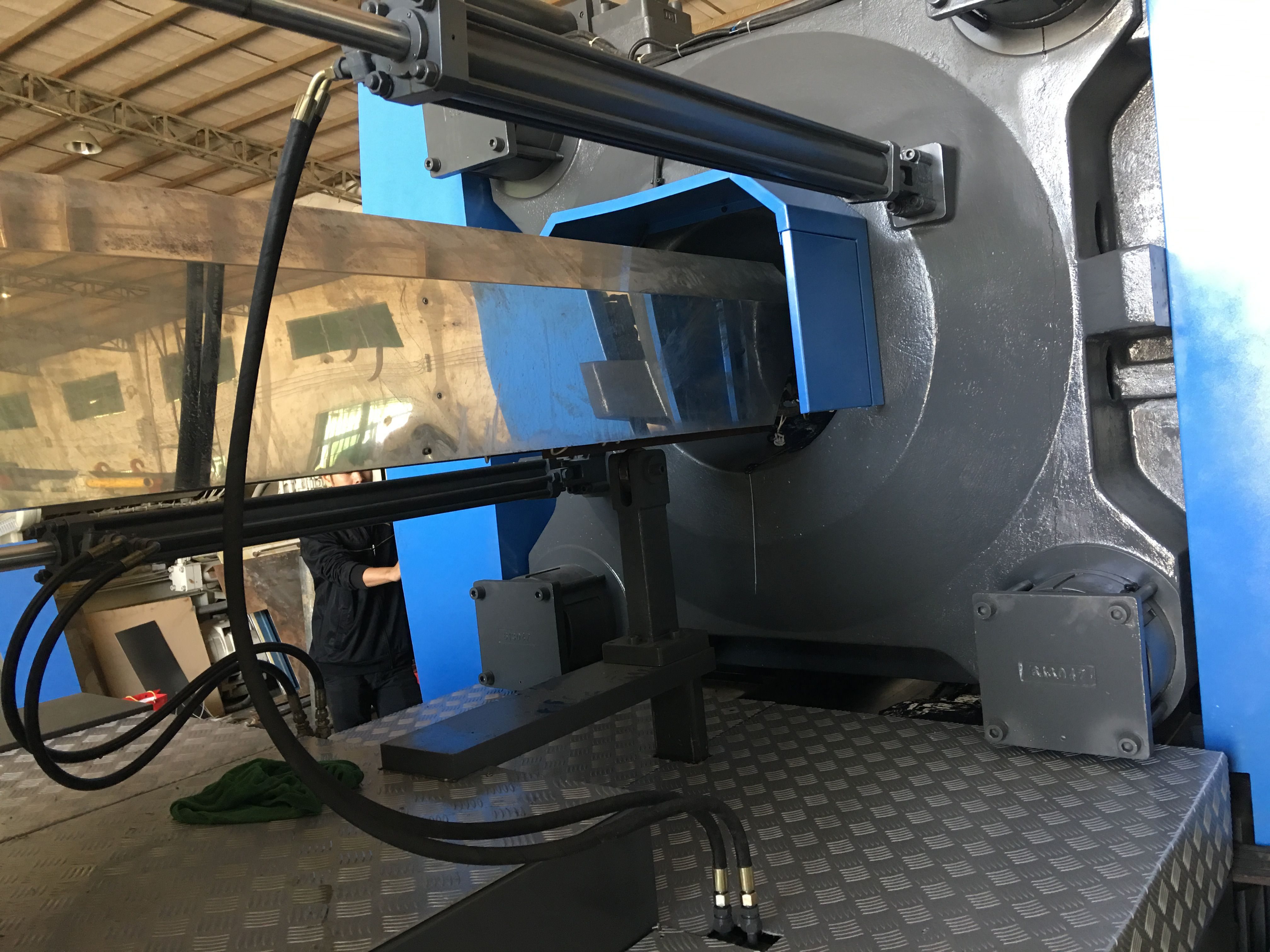

Haitian 1300t (servo) used Injection Molding Machine for sale.

Model: MA13000/10500

Year: 2012.

Tie bar spacing: 1250mm.

Still running production in factory. Good working condition.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

The Precision of Plastic Machining

We stick to our enterprise spirit of "Quality, Performance, Innovation and Integrity". We purpose to create a lot more price for our prospects with our rich resources, innovative machinery, experienced workers and great products and services for OEM/ODM China Haitian 1300t (servo) used Injection Molding Machine Wholesale to Turkmenistan, The product will supply to all over the world, such as: Argentina , Macedonia , Las Vegas , Each product is carefully made, it will make you satisfied. Our products in the production process have got strictly monitored, because it is only to provide you the best quality, we will feel confident. High production costs but low prices for our long-term cooperation. You can have a variety choices and the value of all types are same reliable. If you have any question, do not hesitate to ask us.

This is our plastic injection molding object handling robot. The robot is servo driven and is Euromap12 compatible. This robot is Made in Iran by Mexima ...

Water Damage Restoration? Bay Shore, NY Call (631) 888-6080 Open 24/7, Call Us at (631) 888-6080, or visit our website for more info. Open 24 Hours For Emergencies.

https://westbabylonrestorationpros.com/

https://youtube.com/watch?v=5BSnwS1DtsU

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.