OEM/ODM China Sumitomo 130t All-Electric used Injection Molding Machine to Los Angeles Importers

OEM/ODM China Sumitomo 130t All-Electric used Injection Molding Machine to Los Angeles Importers Detail:

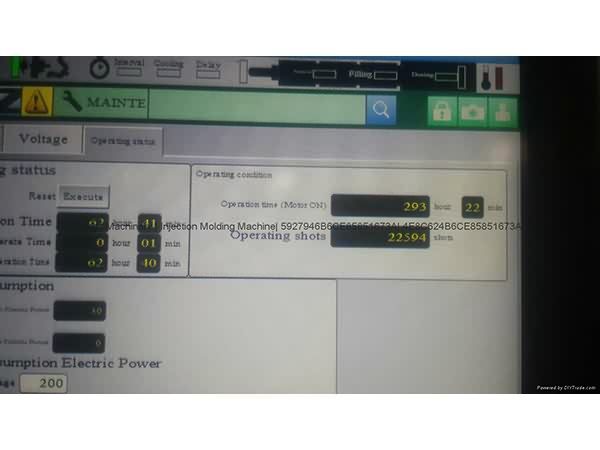

Sumitomo 130t All-Electric Used Injection Molding Machine Video: https://youtu.be/dh8sN_uCzjU Model: SE130EV-C360HP. Year: 2013. Screw diameter: 25/28mm. Injection Speed: 1000mm/s. Tie bar spacing: 510x510mm. 3 units. Machines are in very good and new running condition with less than 300 running hours. They are ultra high speed. Interested customers can visit our warehouse to inspect and test run machines.

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

The Emergence of Injection Molding in Plastic Industry

We are committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for OEM/ODM China Sumitomo 130t All-Electric used Injection Molding Machine to Los Angeles Importers, The product will supply to all over the world, such as: New York , British , Kuwait , Our factory insists on the principle of "Quality First, Sustainable Development", and takes "Honest Business, Mutual Benefits" as our developable goal. All members sincerely thanks for all old and new customers' support. We will keep working hard and offering you the highest-quality products and service.Thanks.

Manual Plastic Embossing Machine Credit Card Embosser

https://www.machinepoint.com/machinepoint/inventory.nsf/idmaquina/300031384?OpenDocument&ln=en&origin=YouTube Email: ...

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.