OEM/ODM Factory Haitian 120t used Injection Molding Machine for London Manufacturer

OEM/ODM Factory Haitian 120t used Injection Molding Machine for London Manufacturer Detail:

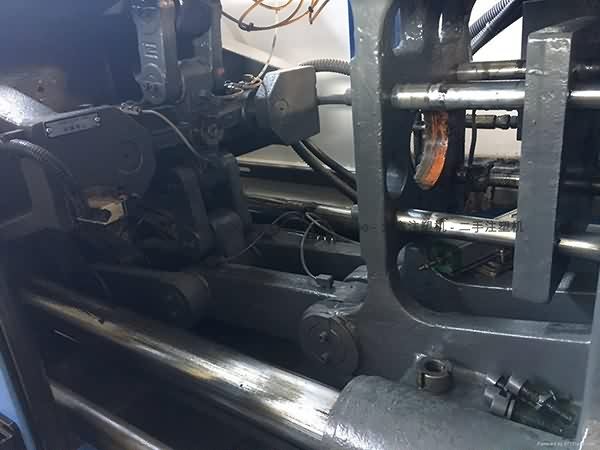

Haitian 120t used Injection Molding Machine

Model: SA1200/370.

Year: 2010.

Screw: A-D34.

Tie bar spacing: 410mm.

Two units. Very good working condition. Interested buyer can visit our warehouse to inspect them and test them running under power.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

How Importers And Exporters Can Benefit From The Canton Fair

We've been convinced that with joint efforts, the enterprise between us will bring us mutual benefits. We could guarantee you item excellent and aggressive price tag for OEM/ODM Factory Haitian 120t used Injection Molding Machine for London Manufacturer, The product will supply to all over the world, such as: United States , Provence , Algeria , In order to carry out our goal of "customer first and mutual benefit" in the cooperation, we establish a specialist engineering team and a sales team to supply the best service to satisfy our customers' requirements. Welcome you to cooperate with us and join us. We have been your best choice.

400 Ton Straight Side Stamping Press For Sale For Sale 616-200-4308, For more information inventory visit our web site https://d3r5f9xr0rb0d5.cloudfront.net/ We buy & sell presses and feedlines. If you have machinery for sale please contact us.

https://s3-us-west-1.amazonaws.com/affordablemachinery/used-metal-stamping-punch-presses-sale/index.html

https://youtube.com/watch?v=8SqCRGZJ4OA

365회 - 김종국, 정은지 강력한 이마 스매싱에 놀란 '얼굴 근육' - 글로벌 레이스 3탄 '쌓이고 프로젝트 반반 투어' 김종국은 정은지에 미션...

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!