OEM/ODM Factory Haitian 160t used Injection Molding Machine to Serbia Manufacturers

OEM/ODM Factory Haitian 160t used Injection Molding Machine to Serbia Manufacturers Detail:

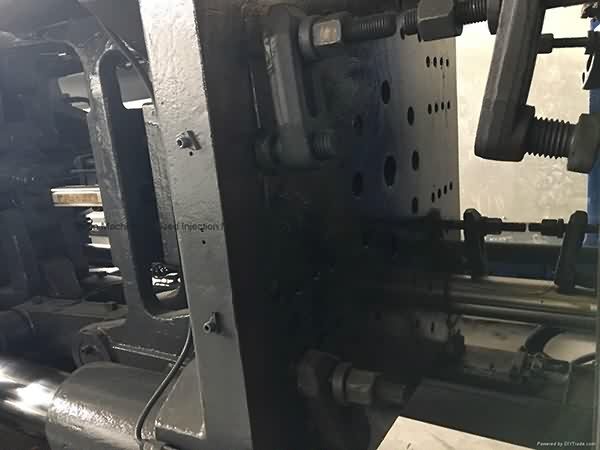

Haitian 160t used plastic injection molding machine.

Model: SA1600/540v.

Year: 2006.

Tie bar spacing: 465x465mm.

Screw diameter: 38mm.

Screw type: B-D38.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

The Emergence of Injection Molding in Plastic Industry

Our mission will be to become an innovative supplier of high-tech digital and communication devices by furnishing benefit added structure, world-class manufacturing, and service capabilities for OEM/ODM Factory Haitian 160t used Injection Molding Machine to Serbia Manufacturers, The product will supply to all over the world, such as: Madagascar , Philadelphia , Romania , Each year, many of our customers would visit our company and achieve great business advancements working with us. We sincerely welcome you to visit us at any time and together we will prevail to a greater success in the hair industry.

Thomas Plastic Machinery, Inc. 812-889-2813 We have for sale a complete stokes vacuum metalizer. It is a full system that was in production before we removed ...

Injection molding of a pen cap connector part from raw materials to finished pen cap part. This video features my new injection molding setup utilizing a 1 ton ...

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!