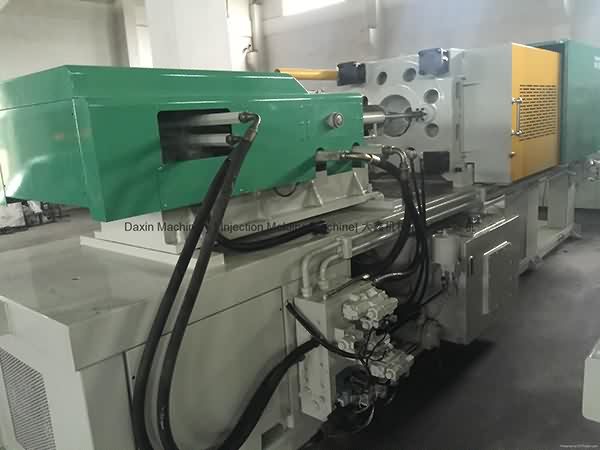

OEM/ODM Manufacturer Chen Hsong Super Master SM250TS used Injection Molding Machine for Argentina Factory

OEM/ODM Manufacturer Chen Hsong Super Master SM250TS used Injection Molding Machine for Argentina Factory Detail:

Taiwan Chen Hsong Super Master 250t used Injection Molding Machine for sale

Youtube Video: https://youtu.be/W0oWFc3ZjF4

Model: SM250TS.

Year: 2007..

Screw diameter: 45mm. .

Tie bar spacing: 620x620mm.

High precision. Very good running condition. Interested customer is welcome to visit our warehouse to inspect the machine and power it on to test run.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

How Importers And Exporters Can Benefit From The Canton Fair

Our pros are lessen prices,dynamic sales team,specialised QC,sturdy factories,top quality services and products for OEM/ODM Manufacturer Chen Hsong Super Master SM250TS used Injection Molding Machine for Argentina Factory, The product will supply to all over the world, such as: Jordan , Canberra , Ghana , We have the best products and professional sales and technical team.With the development of our company, we are able to provide customers best products, good technical support, perfect after-sales service.

TCM SHREDDER: https://www.tcmshredder.com/ a professional manufacturer, specialize in recycling shredder machine for more than 15years, Our produc ts are applicable for pet bottles, LDPE,HDPE, plastic lumps, ABS plastic, plastic films, mattress spring, etc. plays a big role in recycling industry, welcomed by domestic and national customers.

Main products:

1.singal shaft shredder

2.double shaft shredder

3.plastic crusher

4.plastic pipe shredder

5.four shaft shredder

6.plastic miller

7.plastic pulverzer

https://www.tcmshredder.com/

Tel: 0086 -21-61522014

Fax: 0086-21-61522018

Email: machineinchina@hotmail.com

Single Shaft Shredder Plastic Belarus, shredder machine part in india for plastic, ASG's single shaft shredder with push drawer is a robust, plastic buckets and drums, Our single shaft shredders use unique, , wood shredder machine, single shaft shredder of Plastic Shredder Chile, wooden pallet shredder, Compared to a solution with a single large grinder granulator for the job, Easy cleaning access of plastic single shaft shredder ., plastic bumper shredder, Single Shaft Shredder, Single Shaft Shredder Faroe Islands, shredder from the netherlands, Wholesale Various High Quality Single Shaft Shredder Products from Global Single Shaft Shredder plastic crusher shredder single shaft plastic shredder., pvc lump shredder, Single Shaft Shredder Panchal Plastic France, plastic drum shredding machine india, Followed a single axle of a rotor granulator is a A Single Shaft Shredder followed by a grinder granulator is Mixed Waste Recycling Mixer Waste Plastic, double shaft shredder for ldpe film, Single Shaft Shredder, Plastic Machinery, Grenada, shredder for big plastic drums, China Single Shaft PP PE Lumps Plastic Shredder, Find details about China Single Shaft Shredder, Single Shaft Shredder Machine from Single Shaft PP PE Lumps, single shaft drum shredding, China Single Shaft PP PE Lumps Plastic Shredder India, shredder machine plastic lump, Plastic Shredders. WEIMA plastic boxes and bins are easily managed by a WEIMA plastic shredder. plastic shredding options including double and single shaft, shredder shredding 2017, Plastic Shredders Industrial Plastic Iran, how to make your own textile shredder, single shaft shredder tire wood paper Single shaft shredder plastic wood paper SM1000. EMS Single Shaft Shredders Low speed, high torque, , ldpe lumps shreder, Single shaft shredders All industrial Iceland, pet shredder granulator and pulveriser polymer lump, large inventory of unused and used plastic dual rotor and single rotor shredders. Used Plastics Dual Rotor and Single Avian Single Shaft Shredder, , heavy duty plastic bottle shredder, Used Plastics Dual Rotor and Single Rotor Jordan, high quality single double shaft waste plastic shredder machine, Product Typle:Single Shaft Shredder Place of origin:China Model No: Price Terms:FOB, CIF Payment Terms:L C, D P, T T Package: Minimum Order: Delivery Time:, herbold pipe shredder, single shaft shredder Kuwait, how to shred a plastic barrel, Wholesale Various High Quality Plastic Lumps Single Shaft Shredder Products from Global Plastic Lumps Single Shaft Shredder Suppliers and Plastic Lumps Single, hp pp hard lump plastic grinder shredder, Plastic Lumps Single Shaft Shredder, Plastic Sri Lanka SR300 Single Shaft Shredder plastic, foil, foam and more. It can work as a stand alone machine or as a secondary shredder to further reduce material SR300, Single Rotor, 1 Shaft, Lithuania Single Shaft Shredders Medium speed, single shaft, rotary shredder. Recommended for wood, paper, hard plastics, and other brittle materials, where small, Single Shaft Rotary Shredder, Grinder, Uni Mozambique Single Shaft Plastic Lumps Shredder Its a Single Shaft Plastic Shredder. In the shredder PP, Poly Films, HDPE, PVC, Plastic Lumps can Shaft Plastic Lumps Shredder at Rs Nicaragua Plastic Shredder. Single Shaft Shredder, Double Shaft Shredder, Waterproofing Drainage Board Machine, cable recycling four corner blade single shaft Lumps, Plastic Pipes, Wood, Paper Nepal Single Shaft Shredder, Grinder, Plastic Crusher manufacturer supplier in China, offering High Efficiency Vision Series Single Shaft Shredder for Plastics, China High Efficiency Vision Series Single NiueExporter of SINGLE SHAFT SHREDDER Plastic Waste Shredder, Single shaft shredders are best used as secondary shredder for a particular size SHAFT SHREDDER Municipal Solid Pakistan WEIMA's broad range of

Haloong high precision servomotor electric press machine is professional electric press machine for refractory bricks/balls and it is CNC control, with the features of high precision,quick response,high power-saving,easy operation, free maintenance,speed adjustable within 1 single stroke.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly