OEM/ODM Manufacturer JSWJ450EIII used Injection Molding Machine – Servo Used Plastic Machine

OEM/ODM Manufacturer JSWJ450EIII used Injection Molding Machine – Servo Used Plastic Machine Detail:

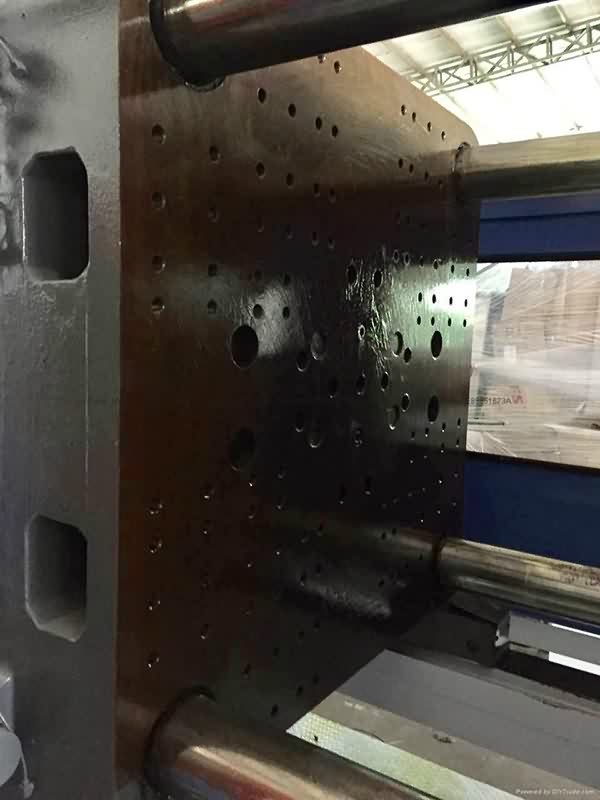

JSWJ450EIII used Injection Molding Machine.

Video:https://youtu.be/CXCqYjH1cto

Model: JSWJ450EIII.

Year: 2006.

Screw diameter: 84mm.

Tie bar spacing: 810x810mm.

Machine is in very good working condition. Interested customer is welcome to visit our warehouse to inspect the machine and test it running under power.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

Plastic Injection Molding: Past, Present and Future

Our commission is always to provide our customers and clientele with best quality and aggressive portable digital products for OEM/ODM Manufacturer JSWJ450EIII used Injection Molding Machine – Servo Used Plastic Machine, The product will supply to all over the world, such as: Sri Lanka , Singapore , Armenia , The working experience in the field has helped us forged a strong relations with customers and partners both in domestic and international market. For years, our products have been exported to more than 15 countries in the world and have been widely used by customers.

During the 1980's the plastic making industry in Taiwan began to take off with many companies subcontracting their operations to Taiwanese suppliers. Through ...

We are the manufacturer who was founded in 1976 and has been manufacturing and selling dies and plastic parts. We develop our business mainly in Japan. Our motto is to focus on improvement of the quality of dies for plastics and plastic parts and to make products without compromise. We, who have thoroughly mastered the knowledge of dies, deliver low-priced yet high-quality products for dies and parts necessary for mass production of automobiles, motorcycles, outboard engines, home electronics, and housing components. In addition, for quality control, we have various inspection facilities including three-dimensional measuring instruments and established the checking system to prevent defective moldings. We respond to customers' needs by the one-stop production system that performs trial production, die making, resin part manufacturing and delivery as well as by our highly value-added products. If you wish to have a quick delivery, cost reduction and high quality, please contact us.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.