OEM/ODM Supplier CLF-200TY used Injection Molding Machines for Puerto Rico Factories

OEM/ODM Supplier CLF-200TY used Injection Molding Machines for Puerto Rico Factories Detail:

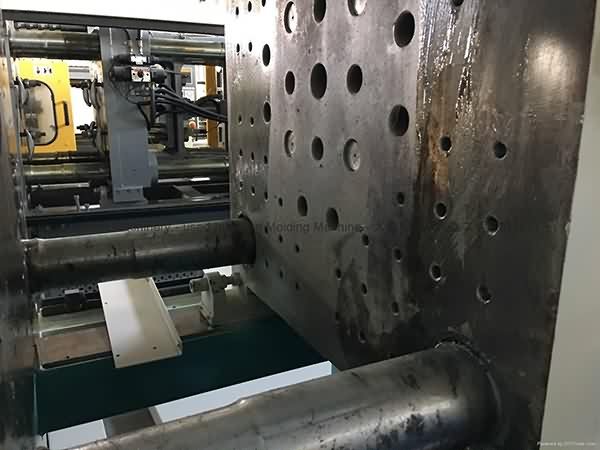

CLF-200TY used Injection Molding Machine.

Model; CLF-200TY.

Year: 2012.

Tie bar spacing: 560x560mm.

Two units available. Very good working condition. Interested customer can visit our warehouse to inspect the machines and test them running under power..

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

The Emergence of Injection Molding in Plastic Industry

The organization keeps on the procedure concept "scientific management, high quality and efficiency primacy, purchaser supreme for OEM/ODM Supplier CLF-200TY used Injection Molding Machines for Puerto Rico Factories, The product will supply to all over the world, such as: Paraguay , Cyprus , San Francisco , Although continuous opportunity, we have now developed serious a friendly relationship with many oversea merchants, such as ones through Virginia. We securely assume that the merchandise regarding t shirt printer machine is often good through a great number of having its good quality and also cost.

・ 月曜定例会・昼の部 - 日本製鋼所への抗議 - [ 2013.06.24 ]

【 お知らせ 】 Channel ☆ K [ https://www.youtube.com/ChannelK2013 ] にチャンネルを移転中です。しばらくは両方のチャンネルから動画をアップしますので、両方ともチャンネル登録を、よろしくお願いします。これからも武田さんのブログ音声、そして現場の映像撮影に努めます。 [ 2013年06月11日 / 清瀬 航輝 ]

場所 : 東京・大崎(昼の部)

日時 : 2013年06月24日(月) 正午過ぎ ~ 午後1時

説明 : 今回は月曜定例会の「昼の部」を撮影しました。なお「夜の部」も撮影していますので、ともにぜひご覧下さい。

・ 月曜定例会・夜の部 - 関西電力、中部電力、両東京支社への抗議 - [ 2013.06.24 ]

→ [ https://youtu.be/BFkkc3IP3cY ]

(以下転載)

脱原発は月曜定例会から、という事で定例の抗議です。

抗議は昼(大崎)と夜(関西電力東京支社&中部電力東京支社)の二部制となりました。

【 昼の部 】

日本製鋼所抗議

ゲートシティ大崎ウエスト(23Fが日本製鋼所本社) 12時 ~ 13時

JR大崎駅前 [ https://p.tl/jfA6 ]

【 夜の部 】

関西電力東京支社への抗議 19時半 ~ 20時半

中部電力東京支社への抗議 20時半 ~ 21時

(ともに地下鉄「内幸町」A7出口を出たところ)

となります。多くの皆様方のご参加を !

月曜定例会(非公式ブログ) [ https://okichi12.jugem.jp ]

撮影 : 清瀬 航輝 - Kiyose Kouki - [ https://kiyose-kouki.jimdo.com ]

(C) STARS LIFE 2013 All Rights Reserved.

[ 福島原発事故 , 福島第一原子力発電所事故 , 福島 , 福島県 , 原発事故 , 東日本大震災 , 東北大震災 , 震災 , 福島事故 , 原子力 , 脱原子力 , 反原子力 , 脱原発 , 反原発 , 原発反対 , 再稼働反対 , 原発再稼働反対 , 大飯再稼働反対 , 大飯原発再稼働反対 , 反原発デモ , 脱原発デモ , 反原発抗議活動 , 脱原発抗議活動 , 首相官邸前 , 官邸前デモ , 官邸前抗議活動 , 経産省前テントひろば , 反原連 , 月曜定例会 , 反被曝 , 脱被曝 , 安倍 晋三 , 安倍首相 , 安倍総理 , 核武装 , 自民党 , 自由民主党 , 日本製鋼所 , ゲートシティ大崎 , ゲートシティ大崎ウエスト , 原子炉メーカー , 軍需産業 , 軍需企業 ]

SOGUTECH.COM

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.