One of Hottest for CLF-1000T (servo) used Injection Molding Machine to Factories

One of Hottest for CLF-1000T (servo) used Injection Molding Machine to Factories Detail:

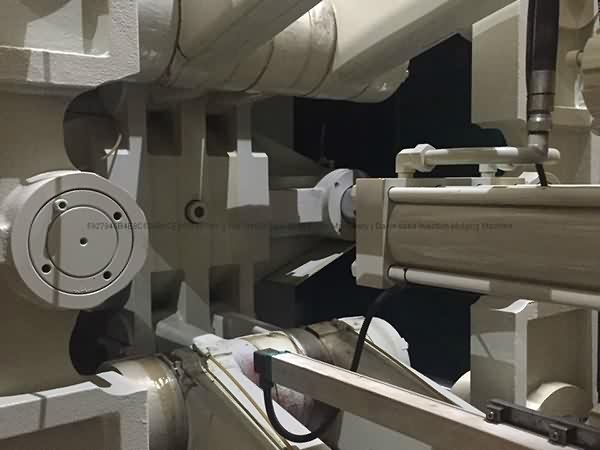

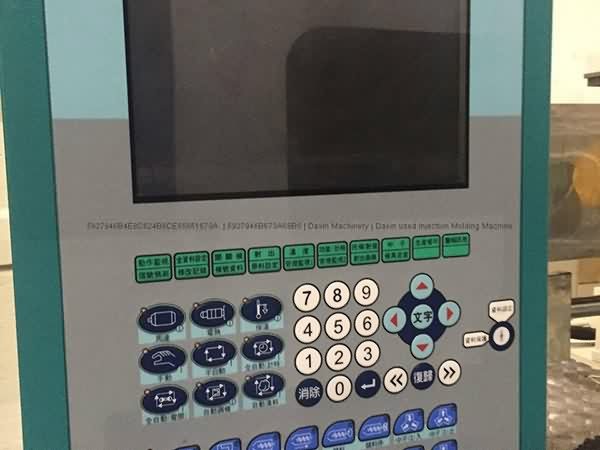

CLF-1000T (servo) used Injection Molding Machine.

Model: CLF-1000T.

Year: 2011.

Screw diameter: 105mm.

Tie bar spacing: 1060mm.

Very good working condition. Interested customer pls visit our warehouse to inspect the machine and test it running under power..

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

The Precision of Plastic Machining

With sophisticated technologies and facilities, strict top quality handle, reasonable value, exceptional support and close co-operation with clients, we are devoted to furnishing the ideal worth for our clients for One of Hottest for CLF-1000T (servo) used Injection Molding Machine to Factories, The product will supply to all over the world, such as: Cairo , Israel , Gabon , In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we will continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

Water Damage Restoration? West Islip, NY Deer Park, NY Call (631) 888-6080 24/7, Call Now (613) 888-6080, or go to our website for more details. Open 24/7 365 days

https://westbabylonrestorationpros.com/

Manufacturers of Water Taps in Coimbatore, Tamilnadu, India. Visit www.leotaps.com for more taps and fittings.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.