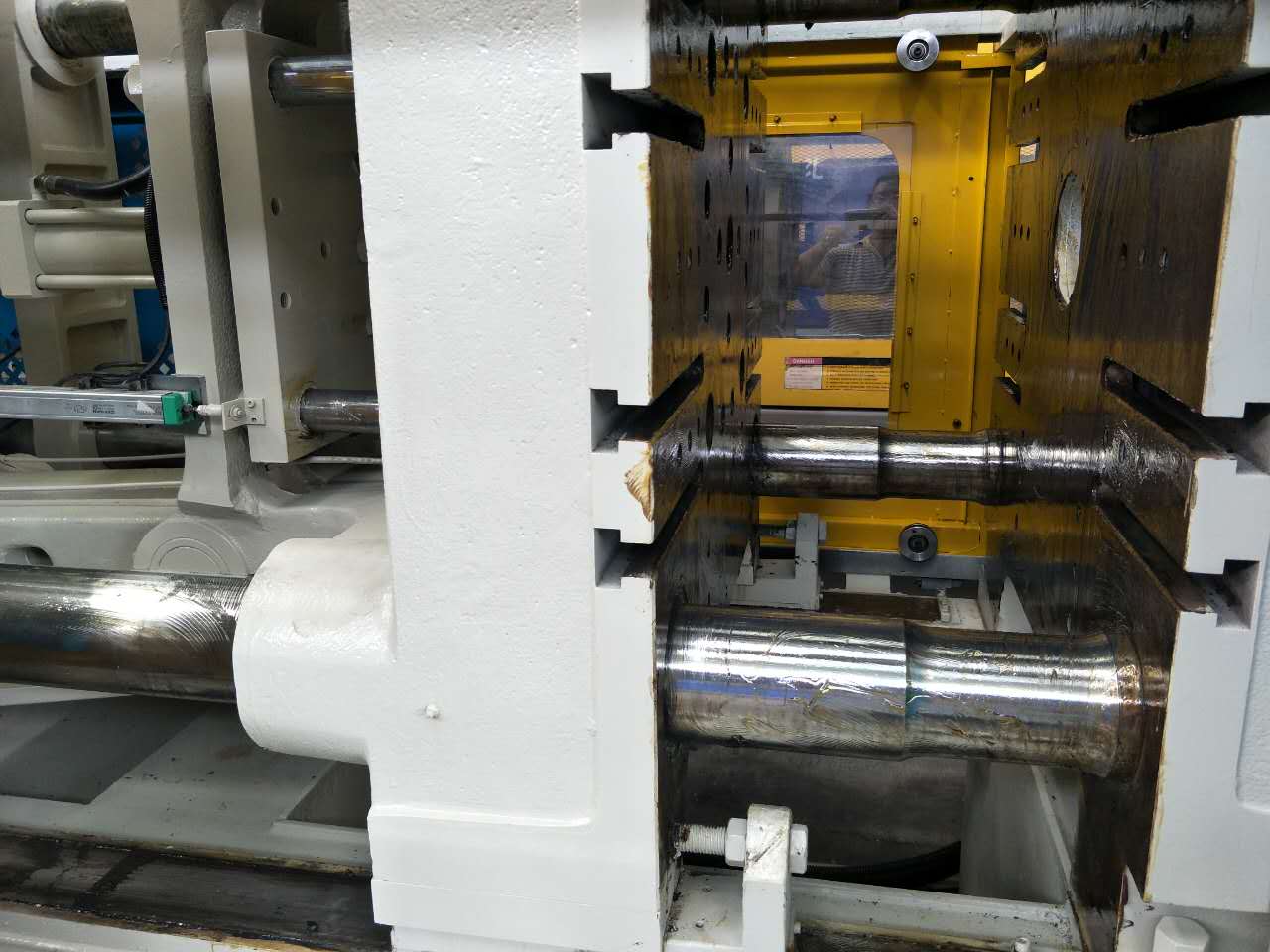

One of Hottest for CLF-400T used Injection Molding Machine Export to Cairo

One of Hottest for CLF-400T used Injection Molding Machine Export to Cairo Detail:

CLF-400T used Injection Molding Machine

Model: CLF-400T.

Year: 2012.

Screw diameter: 60mm.

Tie bar spacing: 680mm.

Good working condition. Interested customer can visit our warehouse to inspect machine and test it running under power..

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

The Precision of Plastic Machining

We are proud of the high customer satisfaction and wide acceptance due to our persistent pursuit of high quality both on product and service for One of Hottest for CLF-400T used Injection Molding Machine Export to Cairo, The product will supply to all over the world, such as: Nicaragua , Riyadh , Sao Paulo , Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

MMC has been supplying cap slitters and TE band inverting machine systems to the closure industry for many years and has advanced the field through innovative machine design.

a) Knotched Knife Slitting Technology

Rotary Cap Slitting machines score the side wall of your plastic closure with arched slitting blade. The slitting blade has intermittent interruptions that will leave a predetermined amount of bridges to hold the Tamper Evident Band to the closure. When the closure is removed from the container for the first time, the bridges break, leaving the band on the neck of the container and demonstrating visual point of purchase tamper evidence to the consumer.

b) Cut-to-post Slitting Technology

A series of ribs are molded into the inner wall of the closure, which will eventually become the bridges that break during closure removal. The closure is rotated against a stationary blade, gradually slicing through the side wall until the blade reaches the molded-in posts.

c) Band Inverter

MMC has launched the CMBF product series to streamline the Tamper Evident Band folding and Band inverting operation. Our unit is a fully automatic multiple head continuous motion machine which is able to fold in the Tamper Evident Band retaining feature allowing the container neck to grip this feature.

For more information, please visit our website

www.mmcpackaging.com

Sutli Making Machine Synthetic String Line Fibrillated Tape Tying Tape

Synthetic String Plant , Sutli Plant, PP Sutli Extruder, Twine Making Machine, Plastic Sutli Plant, Sutli Machine, Pp Sulti Line, Hdpe Synthetic Sutli Plant, Sutli Plant, PP Sutli Plant, PP Sutli Making Machine, PP Sutli Manufacturing Machine, HDPE Sutli Making Machine, Synthetic String Plant

Pp Stitching Twine, Pp String, Packaging Twines, Wrapping Twines, Baler Twines, Tying Twine, Plastic Baler Twines, Split Film Twine, Industrial Tying Twine, Round Baler Split Film, Agricultural Twines, Polypropylene Split Film Twisted Twines, Square Balers Twines, Round Bale Twines, Synthetic Twines, Packing Twine, Bailing Twine, Baling Twine, Baler Twine, Bailer Twine, Reaper Binder Twine,

Tractor Twine, Agricultural Twine, Pp Twine

# Process Material : PP / HDPE

# Electric Panel @ Highest Production Line Capacity in the same class of Machinery

# Specially Designed Control Panel for Saving up to 25% Power Consumption resulting in Optimum Product Costing compared to Conventional Machinery of the same clas

Factory Add : --

OCean Extrusions Pvt Ltd

Plot No. 01, Survey No. 325,

B/h. Jalaram Saw Mill,

Kujad, Daskroi,

Ahemadabad - 382430

Corporate Office :--

Ocean Extrusions Pvt Ltd

B-412, Fourth Floor,

Galaxy Business Park,

Opp. Torrent Power Station,

Sardar Patel ( SP ) Ring Road,

Nikol, Ahemadabad 382415.

www.oceanextrusions.com

9724325401,

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.