One of Hottest for Toshiba IS650GT Used Injection Molding Machine to United Kingdom Importers

One of Hottest for Toshiba IS650GT Used Injection Molding Machine to United Kingdom Importers Detail:

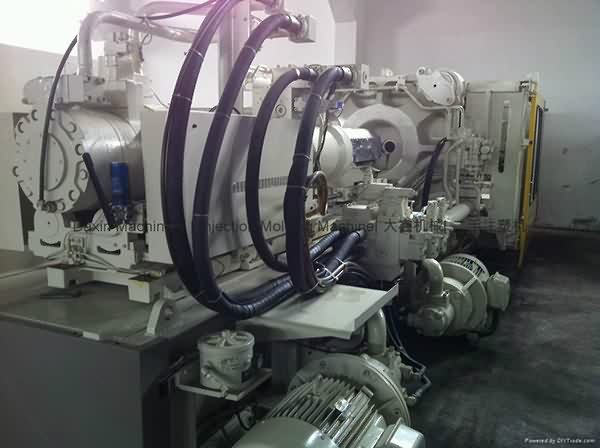

Toshiba 650t used Injection Molding Machine.

Video: https://youtu.be/60tsjjKGmX8

Model: IS650GT-59A.

Screw diameter: 90/95mm.

Tie bar spacing: 980x980mm.

Year: 2004/2006.

Controller type: V10.

Machines are in good working condition. A few units available. Our warehouse is located at ShenZhen of China, very near HongKong and GuangZhou. Interested buyer is welcome to visit our warehouse during Chinaplas to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

How Importers And Exporters Can Benefit From The Canton Fair

With this motto in mind, we have become one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for One of Hottest for Toshiba IS650GT Used Injection Molding Machine to United Kingdom Importers, The product will supply to all over the world, such as: Tanzania , Barbados , Philippines , Our company's main products are widely used all over the world; 80% of our products exported to the United States, Japan, Europe and other markets. All stuff sincerely welcome guests come to visit our factory.

PREVIEW is developing cutting edge wireless technological solutions for injection moulding setup and process optimisation using recommended machine parameters to minimise manufacturing downtime.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 636892.

More info:

preview-project.eu

eurecat.org

Prelude No. 3 de Chris Zabriskie está sujeta a una licencia de Creative Commons Attribution (https://creativecommons.org/licenses/by/4.0/)

Fuente: https://chriszabriskie.com/preludes/

Artista: https://chriszabriskie.com/

Công ty TNHH máy ép nhựa Cheso cung cấp các dòng robot dùng cho máy ép nhựa của hãng SDK. Robot kiểu xoay (swing ), kiểm cánh tay (arm) có một cánh tay, 2 cánh tay, kiểu gập hoặc kiểu thẳng, một ,hai, ba trục dùng động cơ servo.

Liên hệ :

ĐOÀN VĂN TÚ- Sales Engineer

Mobile: 0979.636.232

Email: vantucheso@gmail.com

Skype: doanvantu123

Website: https://www.chesovn.com ; https://www.cheso.com.sg

CÔNG TY TNHH MÁY ÉP NHỰA CHESO VIỆT NAM

Số 6 Lô 5 Khu công nghiệp Lai Xá, Xã Kim Chung, Huyện Hoài Đức, Hà Nội

Điện thoại: (84.4) 36343102 - 36346103 Fax: (84.4) 36343104

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!