Online Exporter CLF-400T used Injection Molding Machine to America Factory

Online Exporter CLF-400T used Injection Molding Machine to America Factory Detail:

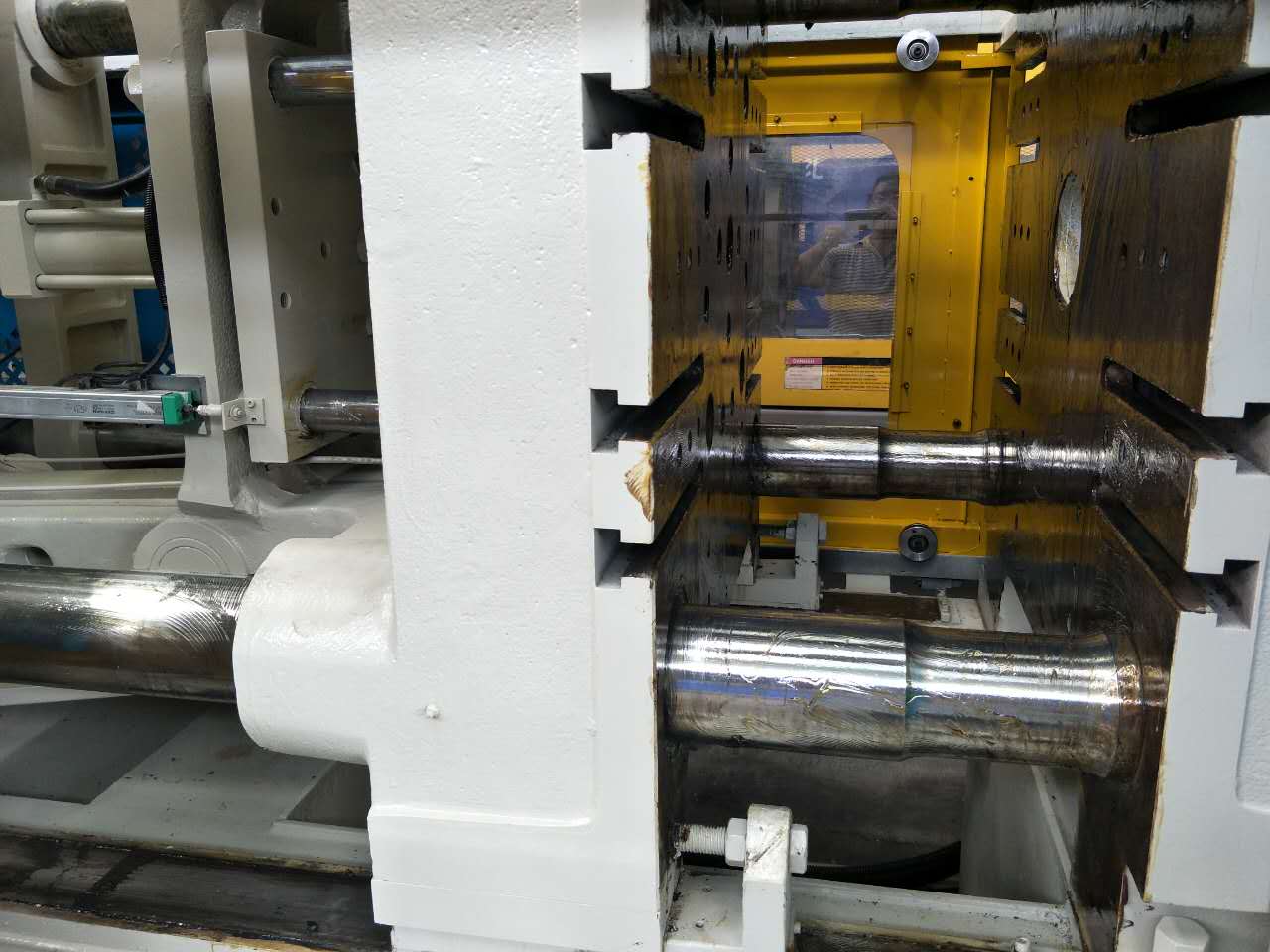

CLF-400T used Injection Molding Machine

Model: CLF-400T.

Year: 2012.

Screw diameter: 60mm.

Tie bar spacing: 680mm.

Good working condition. Interested customer can visit our warehouse to inspect machine and test it running under power..

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

How Importers And Exporters Can Benefit From The Canton Fair

Our team through professional training. Skilled professional knowledge, strong sense of service, to meet the service needs of customers for Online Exporter CLF-400T used Injection Molding Machine to America Factory, The product will supply to all over the world, such as: Rio de Janeiro , Sheffield , Naples , Our mission is "Provide Goods with Reliable Quality and Reasonable Prices". We welcome customers from every corner of the world to contact us for future business relationships and achieving mutual success!

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.