Online Exporter Haitian 250t (servo) used Injection Molding Machine to Cambodia Manufacturers

Online Exporter Haitian 250t (servo) used Injection Molding Machine to Cambodia Manufacturers Detail:

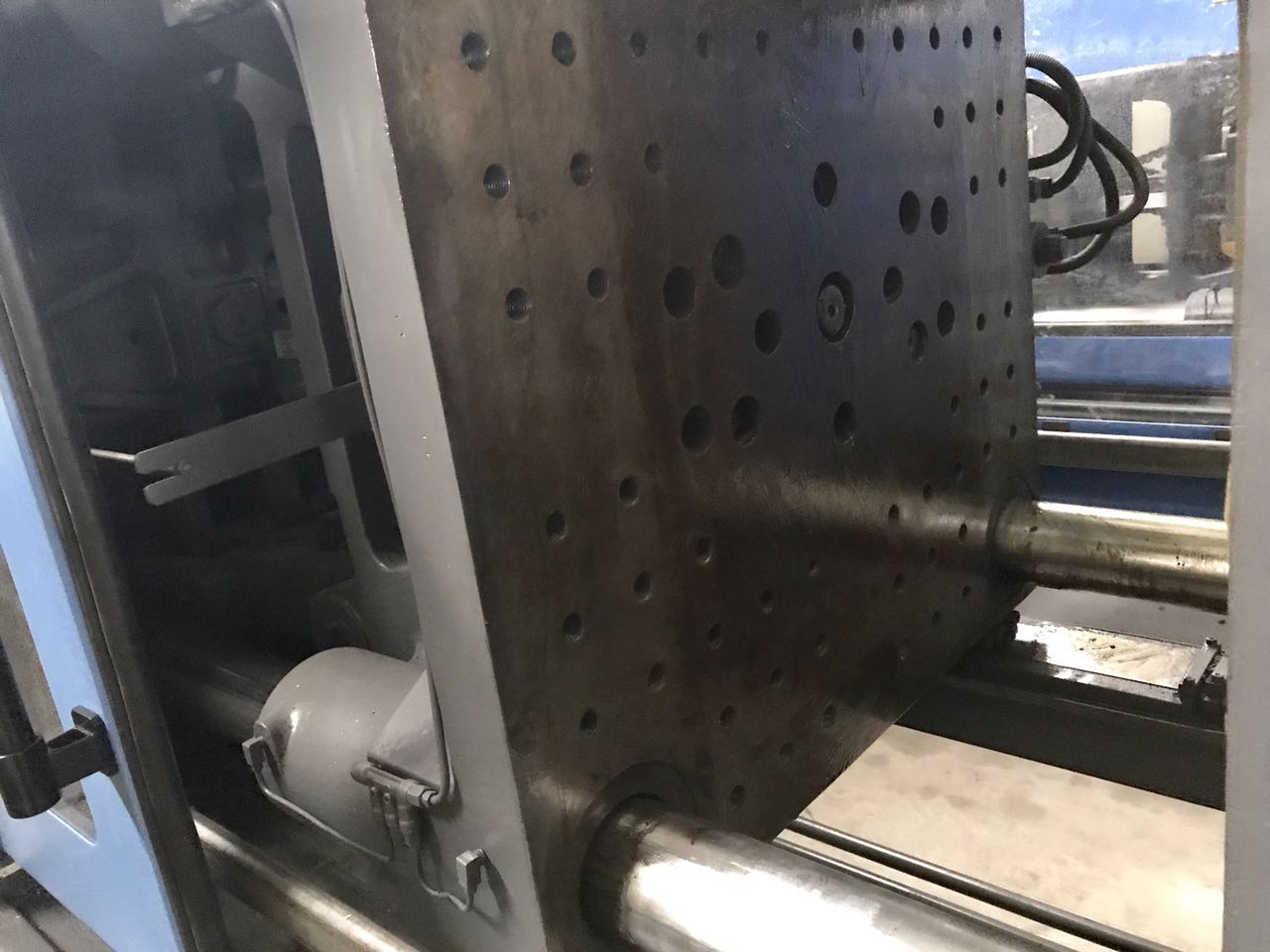

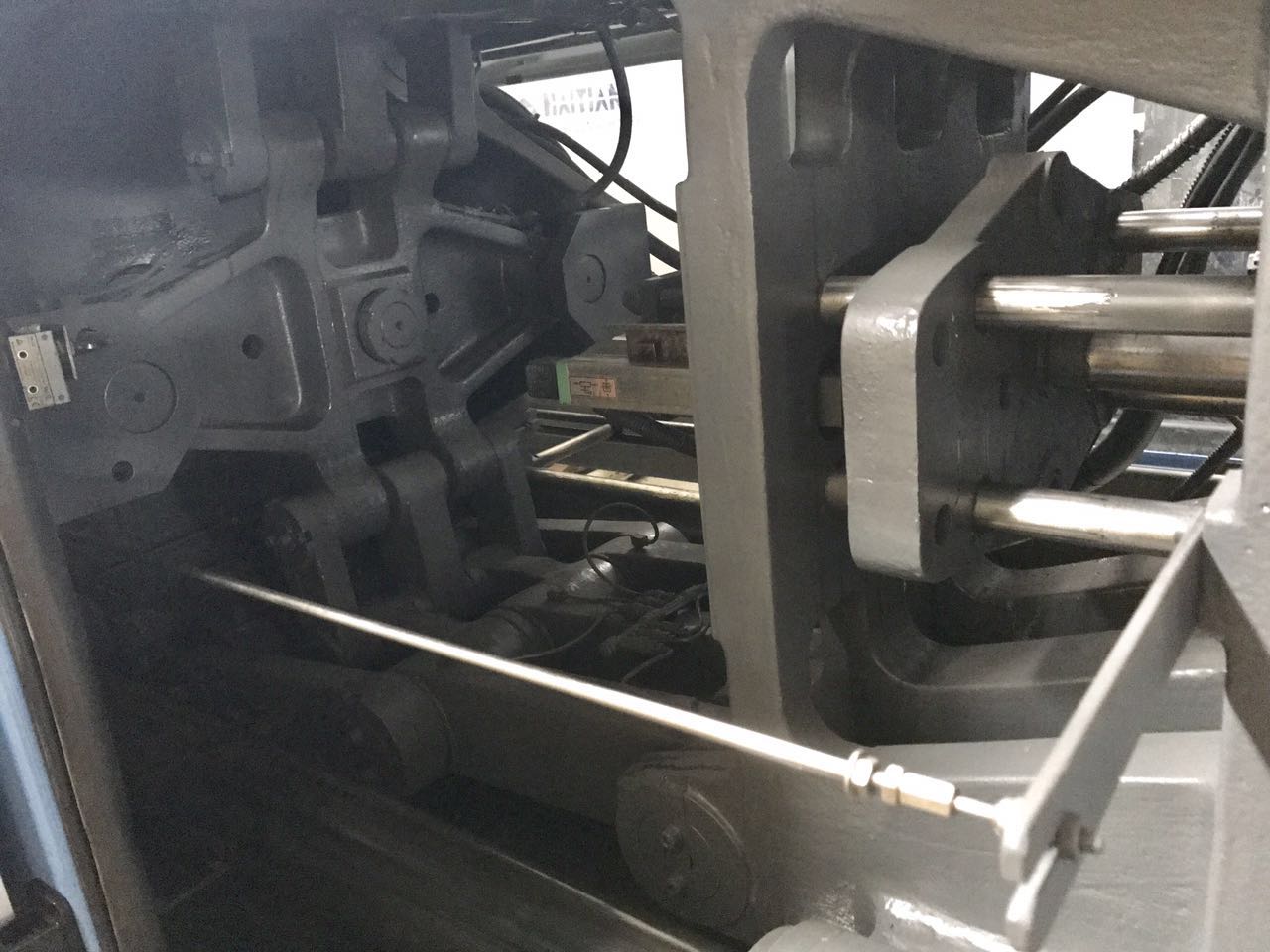

Haitian 250t (servo) used Injection Molding Machine.

Model: MA250.

Year: 2012.

Tie bar spacing: 580x580mm.

Good working condition.

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

How Importers And Exporters Can Benefit From The Canton Fair

All we do is always associated with our tenet " Customer first, Trust first, devoting on the food packaging and environmental protection for Online Exporter Haitian 250t (servo) used Injection Molding Machine to Cambodia Manufacturers, The product will supply to all over the world, such as: Mali , Greenland , South Africa , We will not only continuously introduce technical guidance of experts from both home and abroad, but also develop the new and advanced products constantly to satisfactorily meet the needs of our clients all over the world.

https://www.aaronequipment.com/UsedEquipment/Plastic%20Dies/Die%20Molds/Husky-43216002.html Used- Husky Injection Die Mold. Designed HDPE.

Good day. This is John. From Hong Guan Machinery. With reference to the product offering on your site. May I know if you need a packaging machinery supplies ...

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.