Online Exporter Sumitomo 130t All-Electric used Injection Modling Machine to Roman Factories

Online Exporter Sumitomo 130t All-Electric used Injection Modling Machine to Roman Factories Detail:

Sumitomo 130t All-Electric Used Injection Molding Machine

Video: https://youtu.be/dh8sN_uCzjU

Model: SE130EV-C360HP.

Year: 2013.

Screw diameter: 25/28mm.

Injection Speed: 1000mm/s.

Tie bar spacing: 510x510mm.

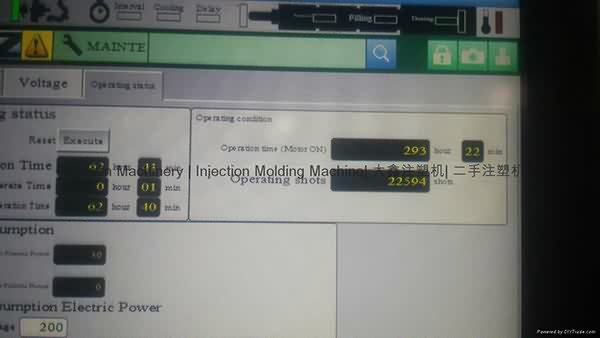

3 units. Machines are in very good and new running condition with less than 300 running hours. They are ultra high speed. Interested customers can visit our warehouse to inspect and test run machines.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

How Importers And Exporters Can Benefit From The Canton Fair

Adhering to your principle of "quality, assistance, performance and growth", we have now gained trusts and praises from domestic and international customer for Online Exporter Sumitomo 130t All-Electric used Injection Modling Machine to Roman Factories, The product will supply to all over the world, such as: Kuwait , Indonesia , Japan , The products has a good reputation with competitive price, unique creation, leading the industry trends. The company insists on the principle of win-win idea, has establishedglobal sales network and after-sales service network.

Gia cong ép nhựa giá rẻ toàn quốc số lượng ít 100- 1000 Sp theo yêu cầu 0932668186 Tuấn.

The lipstick cases have been metallized.------------by

Jane Liu

Hongfeng Mechanical Equipment Manufactory

Website: www.hfvacuum.com

E-mail: info@hfvacuum.com

Address: No.6, Fulin East Road, Jiuhua Industrial Zone, Xiangtan, Hunan, China, 411100

MOBILE(Whatsapp): +86 13789 322 422 Skype: ljieerr

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.