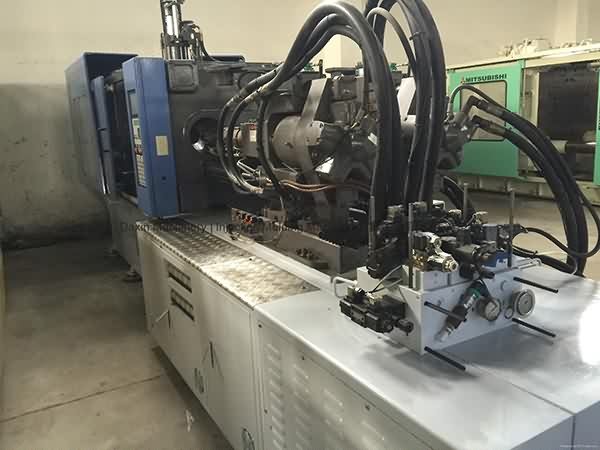

Ordinary Discount Hwa Chin 350t double-color used Injection Molding Machine for Provence Factory

Ordinary Discount Hwa Chin 350t double-color used Injection Molding Machine for Provence Factory Detail:

Taiwa Hwa Chin 350t Double Color used Injection Molding Machine.

Model: DC-350.

Year: 2010.

Screw diameters: 32/32mm.

Tie bar spacing: 650x650mm.

Diameter of rotary table: 950mm.

Very good running condition. Interested customer can visit our warehouse after Chinaplas to inspect and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Making Plastic – Plastic Injection Moulding

We have been convinced that with joint attempts, the business enterprise between us will bring us mutual benefits. We could guarantee you product or service good quality and aggressive value for Ordinary Discount Hwa Chin 350t double-color used Injection Molding Machine for Provence Factory, The product will supply to all over the world, such as: Sri Lanka , South Korea , Canberra , We'll supply much better products with diversified designs and expert services. We sincerely welcome friends from over the world to visit our company and cooperate with us on the basis of long-term and mutual benefits.

www.enjeksiyondaikinciel.com Gsm: 0532 251 02 98.

Plastic Injection Molding Machine-SH KC 200M8-SH 2014 export Algeria.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.