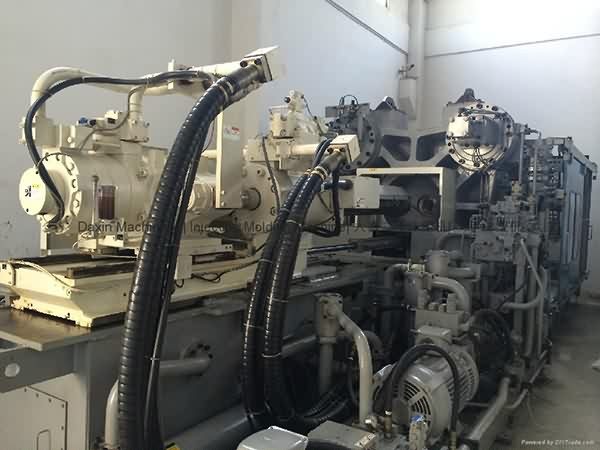

Original Factory Mitsubishi 1300t Used Injection Molding Machine for Rwanda Manufacturers

Original Factory Mitsubishi 1300t Used Injection Molding Machine for Rwanda Manufacturers Detail:

Mitsubishi 1300t used Injection Molding Machine.

Model: 1300MMV-160.

Year of manufactue: 2011.

Tie bar spacing: 1320x1280mm.

Screw diameter: 100mm.

Injection volume: 4540cm^3.

Mould thickness: 700~1200mm.

Clamp stroke: 1800mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

How Importers And Exporters Can Benefit From The Canton Fair

Our commission should be to provide our customers and consumers with ideal top quality and aggressive portable digital products for Original Factory Mitsubishi 1300t Used Injection Molding Machine for Rwanda Manufacturers, The product will supply to all over the world, such as: India , Slovakia , Switzerland , With the spirit of "high quality is our company's life; good reputation is our root", we sincerely hope to cooperate with customers from at home and abroad and hope to build a good relationship with you.

ENGEL victory 160 combi LIM with two injectors and equipped an ENGEL viper robot and with an ELMET complex mold 4+4 cavities and ELMET dosing system ...

JSW J 350AD Full Elektrikli Ambalaj 9 lt Kova.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!