Original Factory Toshiba IS450GS Used Injection Molding Machine for French Factory

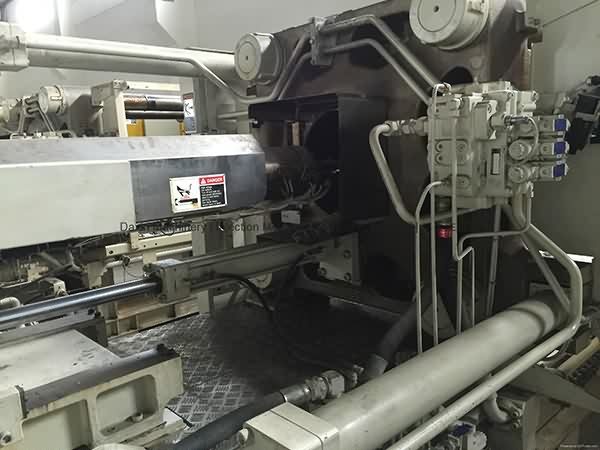

Original Factory Toshiba IS450GS Used Injection Molding Machine for French Factory Detail:

Toshiba 450t used plastic injection molding machine

Youtube: https://youtu.be/WJngGtO1BdI

Model: IS450GS.

Year: 2003.

Screw diameter: 70mm.

Injection weight: 1360g

Tie bar spacing: 810x810mm.

Controller: V10.

A few units for sale. Machines are in good working condition, kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us after Chinaplas to power on the machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Making Plastic – Plastic Injection Moulding

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs of Original Factory Toshiba IS450GS Used Injection Molding Machine for French Factory, The product will supply to all over the world, such as: Turkey , New Delhi , Namibia , We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The items to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

Click below and get a wide information about this Used Machine: https://www.machinepoint.com/machinepoint/inventory.nsf/idmaquina/300034473?

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!