Personlized Products Sumitomo 130t All-Electric used Injection Modling Machine for Pakistan Manufacturer

Personlized Products Sumitomo 130t All-Electric used Injection Modling Machine for Pakistan Manufacturer Detail:

Sumitomo 130t All-Electric Used Injection Molding Machine

Video: https://youtu.be/dh8sN_uCzjU

Model: SE130EV-C360HP.

Year: 2013.

Screw diameter: 25/28mm.

Injection Speed: 1000mm/s.

Tie bar spacing: 510x510mm.

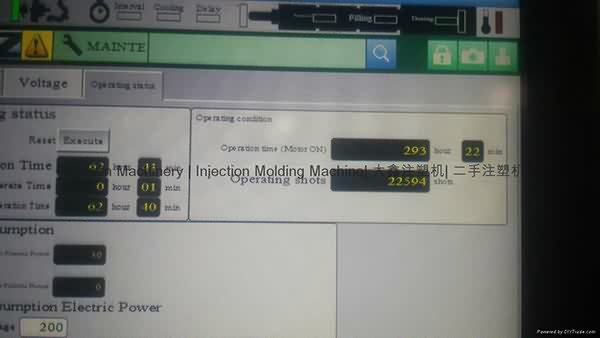

3 units. Machines are in very good and new running condition with less than 300 running hours. They are ultra high speed. Interested customers can visit our warehouse to inspect and test run machines.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

How Importers And Exporters Can Benefit From The Canton Fair

continue to enhance, to be certain solution top quality in line with market and buyer standard requirements. Our corporation has a excellent assurance program are actually established for Personlized Products Sumitomo 130t All-Electric used Injection Modling Machine for Pakistan Manufacturer, The product will supply to all over the world, such as: Denver , Chile , Oslo , As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, please contact us. And It is our great pleasure if you like to have a personally meeting in our office.

INYECTORA SUMITOMO DOBLE HORNO, CONTROLADOR SYCAP MIII

20,000 Lbs Littell Call 616-200-4308 for more information visit us at https://d1a6prx2duc1gy.cloudfront.net/ or Contact Us at 616-200-4308. Available Equipment changes weekly, call for current updates or get on our email updates list. We also sell & buy machines too.

https://s3-us-west-1.amazonaws.com/affordablemachinery/category/metal-working-machinery/coil-handling-equipment/index.html

https://youtube.com/watch?v=ByvUZTjNusc

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!