Popular Design for CLF-1000T (servo) used Injection Molding Machine for Oman Factories

Popular Design for CLF-1000T (servo) used Injection Molding Machine for Oman Factories Detail:

CLF-1000T (servo) used Injection Molding Machine.

Model: CLF-1000T.

Year: 2011.

Screw diameter: 105mm.

Tie bar spacing: 1060mm.

Very good working condition. Interested customer pls visit our warehouse to inspect the machine and test it running under power..

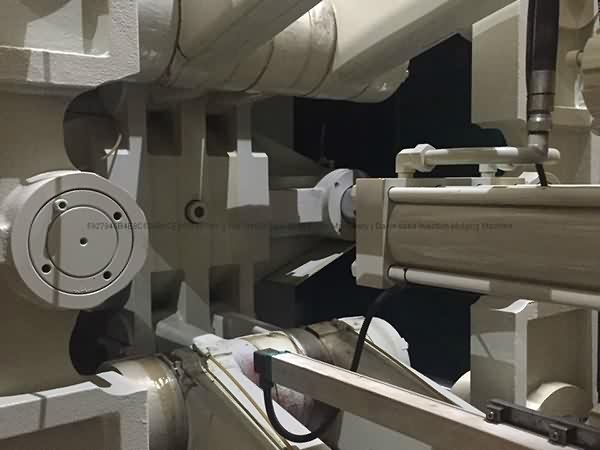

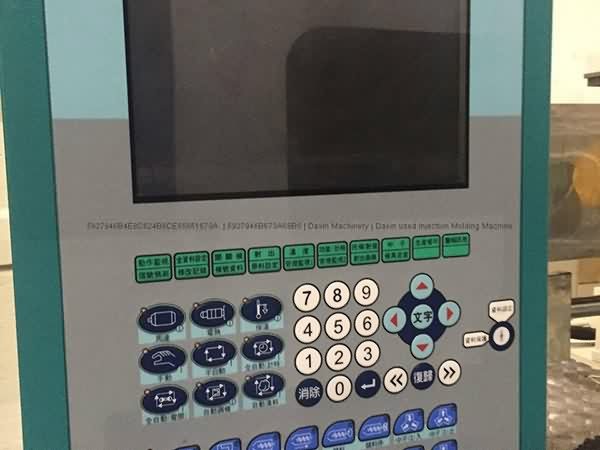

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

How Importers And Exporters Can Benefit From The Canton Fair

With our loaded practical experience and thoughtful solutions, we now have been identified for a trusted provider for numerous intercontinental consumers for Popular Design for CLF-1000T (servo) used Injection Molding Machine for Oman Factories, The product will supply to all over the world, such as: Iraq , New Zealand , Lebanon , Good quality and reasonable price have brought us stable customers and high reputation. Providing 'Quality Products, Excellent Service, Competitive Prices and Prompt Delivery', we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We'll work whole-heartedly to improve our solutions and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

Star Automation TW1000 Full Servo Robot.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.