Popular Design for Nanrong 120t used Injection Molding Machine for Barbados Factories

Popular Design for Nanrong 120t used Injection Molding Machine for Barbados Factories Detail:

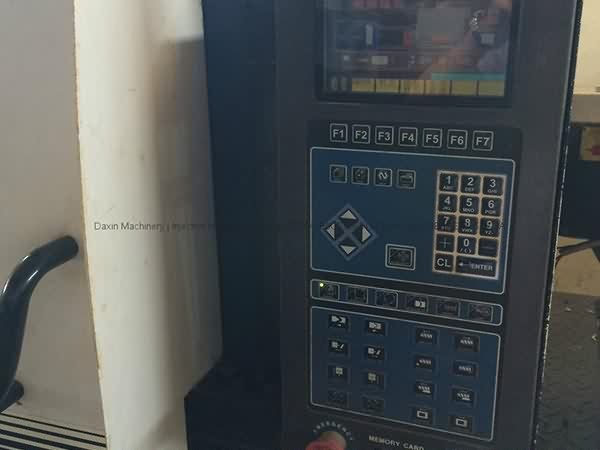

Taiwan Nanrong 120t Used Plastic Injection Molding Machine

Youtube Video: https://youtu.be/Dpld0N3LLpk

Model: 120SA

Tonnage: 120t

Screw diameter: 22mm

Tie bar spacing: 360x360mm

Year: 2006

Machines are in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou.Interested customers can visit us after Chinaplas to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

The Precision of Plastic Machining

Our goal is to provide high quality products at competitive prices, and top-notch service to customers around the world. We are ISO9001, CE, and GS certified and strictly adhere to their quality specifications for Popular Design for Nanrong 120t used Injection Molding Machine for Barbados Factories, The product will supply to all over the world, such as: Spain , Paris , Manila , Customer's satisfaction is always our quest, creating value for customers is always our duty, a long term mutual-beneficial business relationship is what we are doing for. We are an absolutely reliable partner for you in China. Of course, other services, like consulting, can be offered too.

We have experience supplying closing machines for a variety of closures with various hinge styles and latching features. Our closing machines use repeatable and highly efficient techniques to perform intricate closing functions for the following types of closures:

- Flip-Top closures for condiments

- Dispensing closures for the Hair Care market

- Rectangular Coffee closures

- Single-door and twin-door closures for spices and grated cheese & non-dairy creamer

- Beverage closures

- Custom designed hinged closures

For more info: info@mmcpackaging.com

www.mmcpackaging.com

more information available: www.uniplastico.com

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.