Popular Design for Nanrong 120t used Injection Molding Machine for Italy Importers

Popular Design for Nanrong 120t used Injection Molding Machine for Italy Importers Detail:

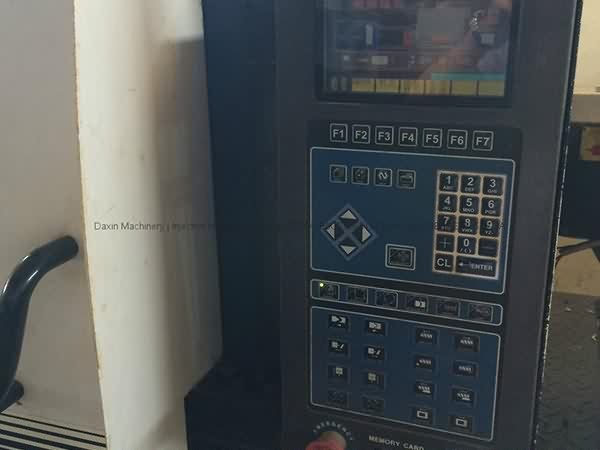

Taiwan Nanrong 120t Used Plastic Injection Molding Machine

Youtube Video: https://youtu.be/Dpld0N3LLpk

Model: 120SA

Tonnage: 120t

Screw diameter: 22mm

Tie bar spacing: 360x360mm

Year: 2006

Machines are in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou.Interested customers can visit us after Chinaplas to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

Plastic Injection Molding: Past, Present and Future

Bear "Customer initially, High-quality first" in mind, we work closely with our prospects and supply them with efficient and specialist companies for Popular Design for Nanrong 120t used Injection Molding Machine for Italy Importers, The product will supply to all over the world, such as: Malta , Qatar , Sao Paulo , Our technical expertise, customer-friendly service, and specialized products make us/company name the first choice of customers and vendors. We are looking for your inquiry. Let's set up the cooperation right now!

Neck up, always neck up, avoid any problem in the whole process.

Huaao Electricity Technology Co.,Ltd is the only supplier who professional produce: APG machine,APG molds,casting mold and instrument transformer winding ...

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!