PriceList for Chuan Lih Fa CLF-950TX used Injection Molding Machine to Netherlands Manufacturers

PriceList for Chuan Lih Fa CLF-950TX used Injection Molding Machine to Netherlands Manufacturers Detail:

Chun Lih Fa CLF-950TX injection molding machine.

Year of manufacture: 2010.

Screw diameter: 80mm.

Tie bar spacing: 1120x1120mm.

Machines are in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

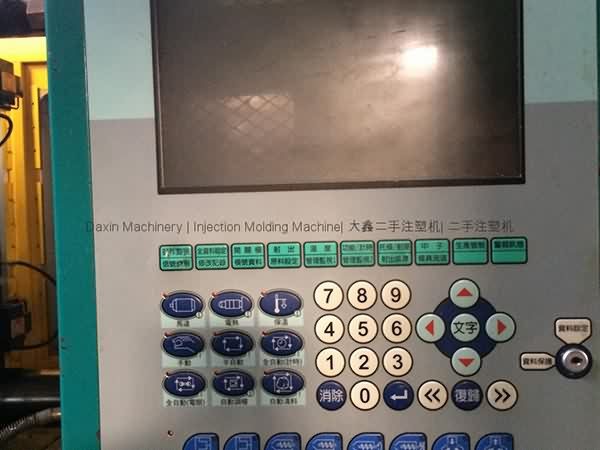

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Making Plastic – Plastic Injection Moulding

We will make just about every exertion for being excellent and perfect, and speed up our actions for standing during the rank of worldwide top-grade and high-tech enterprises for PriceList for Chuan Lih Fa CLF-950TX used Injection Molding Machine to Netherlands Manufacturers, The product will supply to all over the world, such as: Egypt , Luxemburg , Cyprus , Ensuring high product quality by choosing the best suppliers, now we have also implemented complete quality control processes throughout our sourcing procedures. Meanwhile, our access to a large range of factories, coupled with our excellent management, also ensures that we can quickly fill your requirements at the best prices, regardless the order size.

https://www.arburg.com - A two-component injection moulding machine ALLROUNDER 902 S with an innovative 32-cavity cube mould produces in just 10 ...

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.