PriceList for Niigata 180t used All-electric Injection Molding Machine to Marseille Factory

PriceList for Niigata 180t used All-electric Injection Molding Machine to Marseille Factory Detail:

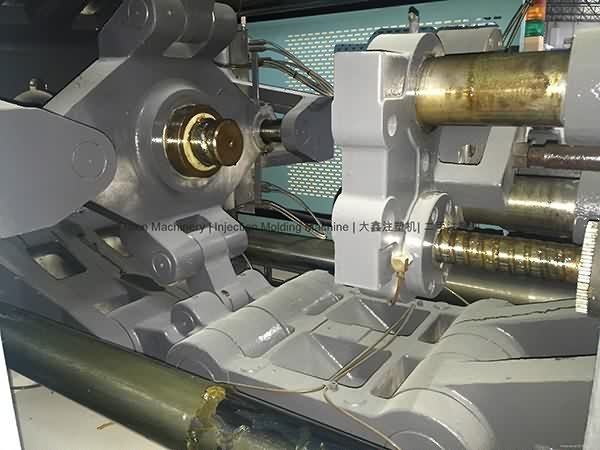

Niigata 180t All-electric used Injection Molding Machine

Youtube Video: https://youtu.be/gdXRtoSqbW0

Model: MD180S-IV.

Year: 2006.

Injection Speed: 300mm/s.

Screw diameter: 35mm.

Tie bar spacing: 510x510mm.

Machines are in good running condition. Two units available. Interested customers are welcome to visit our warehouse to inspect and test machines running.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Making Plastic – Plastic Injection Moulding

We've our have sales staff, style and design staff, technical crew, QC team and package workforce. We've strict excellent control procedures for each system. Also, all of our workers are experienced in printing field for PriceList for Niigata 180t used All-electric Injection Molding Machine to Marseille Factory, The product will supply to all over the world, such as: Sevilla , Brazil , Honduras , All our products are exported to clients in the UK, Germany, France, Spain, the USA, Canada, Iran, Iraq, the Middle East and Africa. Our products are well welcomed by our customers for the high quality, competitive prices and the most favorable styles. We hope to establish business relationship with all customers and bring more beautifu colors for the life.

Information about the Dorman Fuel Line Repair Kit, part number 800-300.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.