PriceList for Toshiba 1300t (wide platen) used Injection Molding Machine for Hungary Manufacturer

PriceList for Toshiba 1300t (wide platen) used Injection Molding Machine for Hungary Manufacturer Detail:

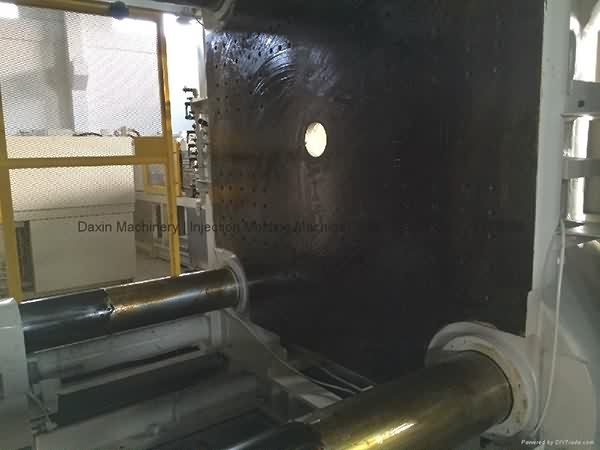

A Toshiba 1300t (wide platen) used injection molding machine for sale.

Model: IS1300DFW-200A.

Year of manufacture: 2004.

Screw diameter: 140mm.

Shot weight:9150g.

Tie bar spacing: 1430x1430mm.

Youtube video: https://youtu.be/hRc5cZvXlFs

Machine has wide platen, it is in good running condition. Interested customer is welcome to visit our warehouse to inspect and test run the machine.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

How Importers And Exporters Can Benefit From The Canton Fair

"Quality first, Honesty as base, Sincere service and mutual profit" is our idea, in order to develop continuously and pursue the excellence for PriceList for Toshiba 1300t (wide platen) used Injection Molding Machine for Hungary Manufacturer, The product will supply to all over the world, such as: Azerbaijan , venezuela , Bangladesh , Our product quality is one of the major concerns and has been produced to meet the customer's standards. "Customer services and relationship" is another important area which we understand good communication and relationships with our customers is the most significant power to run it as a long term business.

30,000 Lbs Used Press Servo Feed Lines For Sale Affordable-Machinery.Com for more details visit us at https://d1a6prx2duc1gy.cloudfront.net/ or Call us at 616-200-4308. Inventory changes daily, call for current updates or get on our email updates list. We also sell & buy machines too.

https://s3-us-west-1.amazonaws.com/affordablemachinery/category/metal-working-machinery/coil-handling-equipment/index.html

https://youtube.com/watch?v=OGSojBNy42c

Injection moulding (injection molding in the USA) is a manufacturing process for producing parts by injecting material into a mould. Injection moulding can be performed with a host of materials, including metals, (for which the process is called diecasting), glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed, and forced into a mould cavity, where it cools and hardens to the configuration of the cavity

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!