PriceList for Toshiba IS450GS Used Injection Molding Machine – Japanese Plastic Injection Molding Machine

PriceList for Toshiba IS450GS Used Injection Molding Machine – Japanese Plastic Injection Molding Machine Detail:

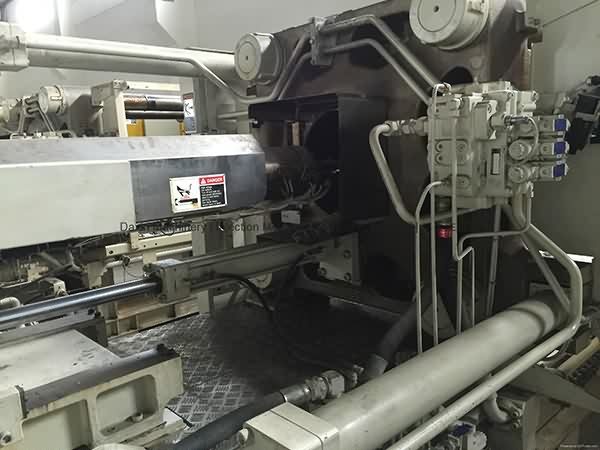

Toshiba 450t used plastic injection molding machine

Youtube: https://youtu.be/WJngGtO1BdI

Model: IS450GS.

Year: 2003.

Screw diameter: 70mm.

Injection weight: 1360g

Tie bar spacing: 810x810mm.

Controller: V10.

A few units for sale. Machines are in good working condition, kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us after Chinaplas to power on the machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Making Plastic – Plastic Injection Moulding

To create extra value for customers is our enterprise philosophy; buyer growing is our working chase for PriceList for Toshiba IS450GS Used Injection Molding Machine – Japanese Plastic Injection Molding Machine, The product will supply to all over the world, such as: Oman , Russia , Buenos Aires , Immediate and expert after-sale service supplied by our consultant group has happy our buyers. Comprehensive Info and parameters from the merchandise will probably be sent to you for any comprehensive acknowledge. Free samples may be delivered and company check out to our corporation. n Morocco for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

We manufacture dual color injection unit,injection machine and moulds by ourself. Sino holdings group is a powerful company with 7 branch companies.

automatic led light bulbs cartoning machine box machine

Contact mail: carol@bochepac.com

Skype: bochepac2

this machine is a automatic cartoning machine, can pack for led bulbs, lamp bulbs, soap, tissue and so on. it will help you automatic form the carton, inserting the products into carton and close it.

Here are two ways of close the carton:

1. by inserting the tongue

2. by hotmelt glue, so it need equipped with the spraying machine.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!