Professional China JSWJ150EIII used Injection Molding Machine Export to French

Professional China JSWJ150EIII used Injection Molding Machine Export to French Detail:

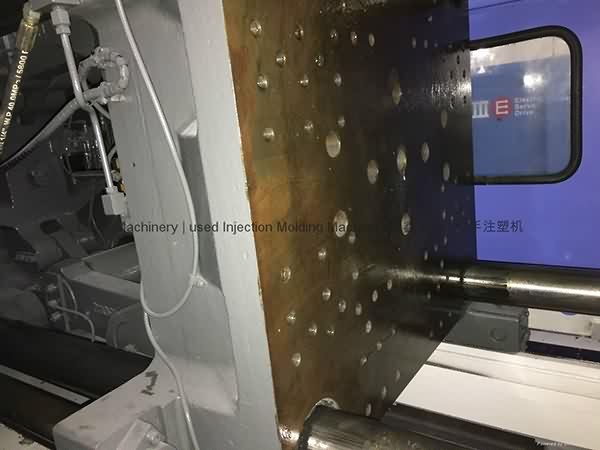

JSWJ150EII used Injection Molding Machine.

Model: JSWJ150EIII.

Year: 2006.

Screw diameter: 46mm.

Tie bar spacing: 510x510mm.

Machine is in very good running condition. Interested customer please visit our warehouse to inspect the machine and test it running under power.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Making Plastic – Plastic Injection Moulding

Our focus on should be to consolidate and enhance the quality and repair of present products, in the meantime constantly establish new products to meet unique customers' requires for Professional China JSWJ150EIII used Injection Molding Machine Export to French, The product will supply to all over the world, such as: Uzbekistan , Ireland , Indonesia , You can always find the products you need in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We are looking forward to work with you for a win-win situation.

TCM SHREDDER: https://www.tcmshredder.com/ a professional manufacturer, specialize in recycling shredder machine for more than 15years, Our produc ts are applicable for pet bottles, LDPE,HDPE, plastic lumps, ABS plastic, plastic films, mattress spring, etc. plays a big role in recycling industry, welcomed by domestic and national customers.

Main products:

1.singal shaft shredder

2.double shaft shredder

3.plastic crusher

4.plastic pipe shredder

5.four shaft shredder

6.plastic miller

7.plastic pulverzer

https://www.tcmshredder.com/

Tel: 0086 -21-61522014

Fax: 0086-21-61522018

Email: machineinchina@hotmail.com

Shredder 2003 Overview Argentina, shredding plastic drums, Overview of Shredder, 2003, with at Turner Classic Movies, plastic shredder hard plastic, Tcm Shredder Used Ldpe Hdpe Pipe Australia, hdpe film shredders, Download Songs Tcm Shredder Used Ldpe Hdpe Pipe Shredder Machine Gambia Latvia Portugal only for review course, Buy Cassette or CD VCD original, cement bag shredding washing and drying machine, plastic shredders, eBay Bangladesh, shredder plastic pet bottles for plastic wood, Find great deals on eBay for plastic shredders. See more like this 30 60 Gallon Plastic Shredder Bags For TAA Compliant Shredders 100 Pack 1145482., indian plastic drum shredder manufacturer, Plastic Shredder Machine Made in Bolivia, germany plastic crusher shredder, China Plastic Shredder Machine, Find details about China Shredder Machine, Plastic Shredder Machine from Plastic Shredder Machine Zhangjiagang Sino Tech, transportable plastic shredder, Plastic Shredders Industrial Plastic Bahamas, plastik scrap shredder models, Plastic Shredders. WEIMA plastic shredders offer various types of rotors, knives and cutting technologies. They are able to process the broad range of thermoplastic, single shaft drum shredding, : Plastic Shredder Canada, industrial cardboard shredder, : Plastic Shredder. Interesting Finds Updated Daily. Amazon Try Prime All Electric powered shredder. Plastic makes up the primary material, paper shredder mechanism, About PROSINO, Shredder Manufacturer, Cyprus, pet hdpe shredder, About PROSINO Brand Providing Customized shredding and crushing granulating Solutions. PROSINO is the popular shredder and granulator brand from Ningbo, ldpe hdpe film shredding machine single screw, Plastic recycling shredder Manufacturers Estonia, shred engine block, China plastic recycling shredder manufacturer factory list, find qualified Chinese plastic recycling shredder manufacturers, suppliers, factories, exporters Sign In, plastic tile pipe shredder, Used Plastics Shredders for sale. Zeno and El Salvador, shredder plastic machine, Search 229 listings for used plastics shredders. Find Zeno, Vecoplan, Menart, Lindner 48489001 used re tech plastic shredder, model: rg 52. 100 hp, single, coast of shreding machine, HSM Classic, 22 24 Sheet, Strip Cut, Britain, indusrial cardboard shredder machine, Buy HSM Classic, 22 24 Sheet, Strip Cut, 13 Gallon Capacity Shredder: Everything Else FREE DELIVERY possible on eligible purchases, shred plastic bags, Shredding Machines, Shredding Machines Ghana The comprehensive range of products we deal in includes Shredding Machines, Waste Reduction Machines, PLASTIC Bags Shredder: Plastic Shredding: Chipper Shredder:Plastic Recycling Machine, Plastic Shredder Ireland Plastic Grinder, Plastic Recycling Machine, Plastic Granulator. As you read this, Vecoplan plastic shredder machines are shredding ABS, Acetal, Acrylic, Plastic Shredder, China Plastic Shredder Israel China Plastic Shredder manufacturers Select 2017 high quality Plastic Shredder products in best price from certified Chinese Plastic Union manufacturers, Plastic Shred Tech Plastics Shredding Recycling Kuwait Plastics Shredding Recycling Shred Tech custom designs and manufactures Plastic Shredding Systems to reclaim The shredder replaced a pinch roller ahead of Heavy Duty Plastic Shredders ZERMA New Zealand Plastic shredder and large plastic shredding systems for plastic, PVC and vinyl recycling and size reduction by Industrial Plastic Shredders China Industrial Plastic Puerto Rico China Industrial Plastic Shredders, Find details about China Industrial Plastic Shredders, Plastic Shredder from Industrial Plastic Shredders Changshu Shouyu Machinery Things to Know About Shredding, Shredder Qatar About Shredding SSI Shredding and tend to be broken or shattered in a shredder when the cutters aren't sharp or are loose. like a plastic form, China Prices of plastic recycling shredder China plastic Singapore

INJECTION MOULDING MACHINE FOR THERMOPLASTICS

PRESSE AD INIEZIONE PER TERMOPLASTICI

www.plasticmetal.it

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.