professional factory for Chen Hsong Super Master SM250TS used Injection Molding Machine to Stuttgart Importers

professional factory for Chen Hsong Super Master SM250TS used Injection Molding Machine to Stuttgart Importers Detail:

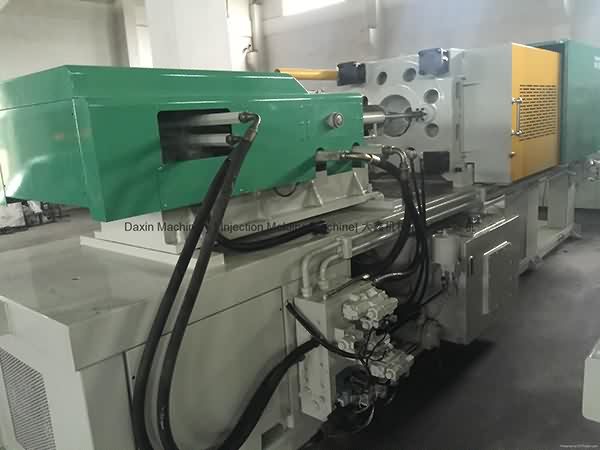

Taiwan Chen Hsong Super Master 250t used Injection Molding Machine for sale

Youtube Video: https://youtu.be/W0oWFc3ZjF4

Model: SM250TS.

Year: 2007..

Screw diameter: 45mm. .

Tie bar spacing: 620x620mm.

High precision. Very good running condition. Interested customer is welcome to visit our warehouse to inspect the machine and power it on to test run.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Making Plastic – Plastic Injection Moulding

Our well-equipped facilities and great excellent command throughout all stages of generation enables us to guarantee total customer fulfillment for professional factory for Chen Hsong Super Master SM250TS used Injection Molding Machine to Stuttgart Importers, The product will supply to all over the world, such as: Jamaica , Naples , Houston , Now, we are trying to enter new markets where we do not have a presence and developing the markets we have the already penetrated. On account of superior quality and competitive price , we will be the market leader, please don’t hesitate to contact us by phone or email, if you are interested in any of our products.

Manual Spacer Bar Round Curve Bender,Manual Spacer Bar Round Bender,Spacer Bar Curve Bending Machine,Spacer Bar Curve Bender,Aluminum Spacer Bar Curve Bending Machine,Aluminum Spacer Bar Curve Bender,Spacer Bar Round Bender,Spacer Bar Round Bending Machine,Aluminum Spacer Bar Bender,Aluminum Spacer Bar Bending Machine,Manual Spacer Bar Round Bender,Semi-Automatic Spacer Bar Round Bender,Manual Spacer Bar Round Bending Machine,Manual Aluminum Spacer Bar Bender,Manual Aluminum Spacer Bar Bending Machine,Semi-Automatic Spacer Bar Round Bending Machine,Semi-Automatic Aluminum Spacer Bar Bender,Semi-Automatic Aluminum Spacer Bar Bending Machine,Manual Spacer Bar Curve Bending Machine,Manual Spacer Bar Curve Bender,Manual Aluminum Spacer Bar Curve Bending Machine,Manual Aluminum Spacer Bar Curve Bender,Manual Spacer Bar Curve Bending Machine,Semi-Automatic Spacer Bar Curve Bender,Semi-Automatic Aluminum Spacer Bar Curve Bending Machine,Semi-Automatic Aluminum Spacer Bar Curve Bender,Semi-Automatic Spacer Bar Curve Bending Machine,Semi-Automatic Spacer Bar Curve Bender,Semi-Automatic Aluminum Spacer Bar Curve Bending Machine,Semi-Automatic Aluminum Spacer Bar Curve Bender

If any interested in it,pls send emails to sales@saintbestgroup.com or saintbestgroup@163.com or add Skype:allenszj for direct conversation.

URL:www.saintbestgroup.com www.doubleglazingequipment.com www.digitaluvprinter.com www.shuntaitech.com

Whatsapp/Wechat:+86-186-6042-5078

Watch this video to see how the latest MAGMASOFT® metal flow simulation technology enables RCM’s engineers to determine the best process parameters for ensuring part quality.

Before production, our simulation experts use RCM’s industry leading gate and runner design techniques to determine the best point to inject molten metal into a die, ensuring you receive finished parts with the best density and structural features possible.

Discover More @ RCMIndustries.com

Call 847-455-1950

Email us at sales@rcmindustries.com

Subscribe for more videos!

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!